Introduction: Why Pneumatic Conveying is a Core Technology in Modern Industry

The effective transportation of bulk material is a basic operation in contemporary manufacturing and processing. Whether it is fine food products or abrasive industrial minerals, the problem is the same: how to move dry bulk materials efficiently, safely, and with the least contamination or loss. Although there are myriads of mechanical conveying systems, including belts, screws, and bucket elevators, the beautiful and mighty principle of pneumatic conveying has proven to be a fundamental technology in an incredible variety of industries. This conveying system offers a unique set of advantages over traditional methods.

This is not a new science. The basic concept of air as a medium of transporting objects is as ancient as the wind. However, its use in regulated, closed industrial settings is a zenith of process engineering. It is a technology that provides unmatched flexibility whereby materials can be transported over, under, and around existing equipment using a sealed and enclosed pipeline, which effectively contains dust and safeguards both the product and the plant environment. For the engineer who has to design, optimize, or maintain a production line, a thorough knowledge of the pneumatic conveying system is not only helpful, but it is a necessity.

This is a guide that is designed to suit you. It goes beyond the shallow definitions to give a strict, practical analysis of the technology. We will unravel the main principles according to which it functions, maneuver through the key differences between the primary types of pneumatic conveying, deconstruct the system into its key system components, and assess its strategic strengths and weaknesses. We want to provide you with the knowledge to not only know pneumatic conveying but also use it as a potent means of solving complicated material handling problems.

Core Principles: How Does Pneumatic Conveying Actually Work?

*This video explains the working principle of the pneumatic conveying system.

In its simplest form, pneumatic conveying is a simple principle that is based on a simple law of physics: fluids, such as air, will flow out of a region of increased pressure to a region of decreased pressure. We produce a controlled air stream by establishing a pressure differential in a closed pipeline. When bulk solidsare added to this moving gas stream, they are swept away from one or more material intake points to a destination. The beauty of the system is that it uses this invisible power of conveying air to perform heavy labor.

The success of any pneumatic conveying system is determined by an accurate combination of three important variables:

- Differential Pressure: This is the engine of the system. It can be created in two ways. In a positive pressure system, a blower or compressor is used at the beginning to force air through the line, which carries the conveyed material. On the other hand, a negative pressure (or vacuum) system involves a blower at the destination to pull air through the line, which carries material with it. The size of this pressure differential in PSI or bar determines the force of motive that can be used to overcome friction and move the material.

- Air Velocity: This is the gas velocity of the air flowing in the pipeline, which is usually expressed in feet per minute (FPM) or meters per second (m/s). It is a very important parameter that should be strictly regulated, especially considering the material’s particle size and density. The velocity should be sufficient to carry the material particles at the feed point and maintain them in the air stream during the conveying process. This is the lowest speed that is necessary and is called the saltation velocity. When the velocity decreases to this level, the particles will start to fall out of the air stream and accumulate at the bottom of the pipeline, causing blockages and system failure. Nevertheless, toohigh air velocity is not only inefficient, using more energy, but also can be destructive, abrading the pipeline and causing particle attrition or damage to the material itself.

- Solids-to-Air Ratio (or Solids Loading Ratio – SLR): This ratio is used to determine the concentration of material in the pipeline. It is the weight of the material being transported divided by the weight of the air transporting it. A low SLR means that the mixture is very lean (sometimes called lean phase) with a large ratio of air to solids whereas a high SLR means that the mixture is dense and heavily loaded. This ratio is not only a measure of efficiency, but the main factor that makes the two major modes of pneumatic conveying different. These three variables are the basis on which all successful system design and operation is based on understanding and control.

The Two Faces of Pneumatic Conveying: Dense Phase vs. Dilute Phase

While the underlying principle of using air to move bulk material is universal, the method by which it is accomplished splits the technology into two distinct, fundamentally different regimes: dilute phase and dense phase. An engineer’s ability to discern which method is appropriate for a given application is paramount to designing a type of system that is not only functional but also efficient, reliable, and cost-effective.

Dilute Phase Conveying: High Speed, Low Concentration

*This video shows Dilute Phase Conveying System

The more intuitive and common of the two conveying methods is dilute phase conveying. Material particles in this regime are completely suspended in a high-velocity air stream and transported singly.

- Operating Characteristics: The most important distinguishing features are high air velocity (usually >3,500 FPM or 18 m/s) and low solids-to-air ratio (SLR is usually less than 15:1). The system is run at comparatively low pressures, utilizing either positive pressure systems or vacuum systems.

- Mechanism: Since the material is dispersed, the system depends nearly solely on the speed of the air to sustain the particles in the air and in motion, similar to a fast-flowing river with tiny grains of sand.

- Ideally Suited: Non-abrasive, non-friable materials in which product degradation is not a major issue. This contains substances such as flour, sugar, and fine dry powders. It is a simple and less expensive device that is used in simple applications.

- Limitations: The higher velocities are very destructive both to the system and the material. Abrasive materials such as sand or cement will quickly wear away pipe bends, whereas fragile materials such as coffee beans, plastic pellets, or flaked cereals may break when struck, producing unacceptable amounts of fine dust and wasted material.

Dense Phase Conveying: Low Speed, High Concentration

*This video shows Dense Phase pneumatic conveying system working principle

A more advanced and milder method is dense phase conveying. It does not suspend particles in a high velocity air stream, but instead transfers material in coherent plugs or slugs along the pipeline at low velocity, a phenomenon often called slug flow.

- Operating Characteristics: This dense phase pneumatic mode is characterized by low air velocity (usually 200-1,200 FPM or 1-6 m/s) and a very high solids-to-air ratio (SLR is often greater than 30:1). It therefore needs more operating pressures, often requiring high pressure, to force these thick plugs of material through the line.

- Mechanism: The driving force is the pressure of the conveying gas on the backside of a slug of material, similar to a piston. The material flows as a unit mass, and the particles have little contact with one another or the walls of the pipes. To sustain the pressure gradient and ensure the slug flows smoothly, the system may need additional air injectors along the line.

- Ideally Suited: Abrasive or friable materials. Since the velocities are low, the erosion of pipes and damage to the product are minimized significantly. This renders it the best option when dealing with materials such as silica sand, cement, glass-filled pellets, and delicate food products. It is also very good in the transfer of mixed materials since the low velocity does not allow the separation of particles of various sizes and bulk densities.

- Limitations: A dense phase system usually requires a higher initial capital cost because it requires a high-pressure air source and a pressure vessel (transporter) to supply material into the line. The control systems are also more complicated.

Key Decision Factors: How to Choose Between Dense and Dilute Phase

The choice of the right conveying phase is a very important engineering choice. The decision on the best way to proceed depends on the careful examination of four aspects:

| Factor | Dense Phase | Dilute Phase |

| Material Properties | Abrasive, friable, or a mix of particle sizes lead to dense phase. | Friable and abrasive granular materials typically lead to dense phase. |

| Conveying Distance | Operates over long distances more efficiently, requires less air volume. Total distance and number of bends are crucial. | Can convey over long distances, but typically requires higher air volume, less energy-efficient over long distances. |

| Throughput Rate | Affects the size of pipes and the selection of air mover; can handle higher throughput rates more effectively. | The required flow rate impacts the pipe size and air mover choice. Lower throughput rates compared to dense phase. |

| Capital vs. Operating Cost | Higher initial cost but saves on energy, maintenance, and product loss over time. | Lower initial cost, but higher operational costs due to energy usage and maintenance, especially with abrasive materials. |

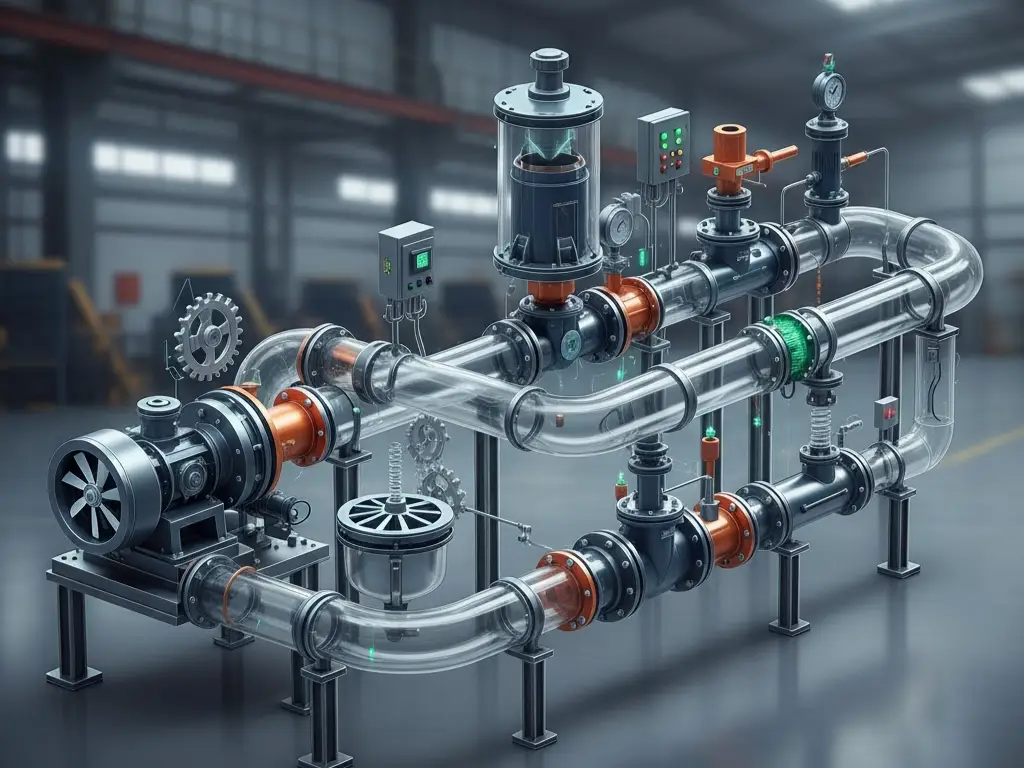

A Comprehensive Breakdown of Key System Components

A pneumatic conveying system is more than just a pipe and a blower. It is an integrated assembly of specialized system components, each performing a critical function. The reliability and efficiency of the entire system depend on the proper selection, sizing, and integration of these parts for any new system.

The Power Source: Blowers, Fans, and Compressors

It is the air mover of the system, which produces the necessary airflow and pressure.

| Type of Air Mover | Description |

| Positive Displacement (PD) Blowers | The workhorse of most dilute and some dense phase systems. They provide a comparatively steady amount of air at varying pressures. |

| Centrifugal Fans | Appropriate for dilute phase systems with very low pressure, where a small pressure differential is required. |

| High-Pressure Compressors | Needed in high pressure dense phase systems. Usually rotary screw or reciprocating compressors capable of producing the high pressure required to propel heavy plugs of material. |

The Feeding Mechanism: Rotary Valves, Screw Feeders, and Venturi Eductors

This element feeds material from a feed hopper into the conveying line at a regulated rate and keeps the pressure seal.

| Device | Description |

| Rotary Airlock Valves | The most widespread feeding device. A rotary airlock consists of a vaned rotor that rotates in a close-fitting housing, sweeping material from a hopper above and into the conveying line below, with a minimum of air escaping. |

| Screw Feeders | Applied to materials that are not free-flowing or need to be metered into the line with accuracy, such as certain batch ingredients. |

| Venturi Eductors | A simple device with no moving parts, applied in dilute phase vacuum systems. The speed of conveying air through the throat of the venturi forms a vacuum that pulls material into the line. |

| Pressure Vessels (Transporters) | Necessary in dense phase systems. A load of material is placed in a coded pressure vessel, which is then closed and pressurized to inject the material as a slug into the pipeline. |

The Pathway: Piping, Bends, and Diverters

This is the network of pneumatic conveying lines which carry material.

| Factor | Details |

| Piping | The choice of pipe material (e.g., stainless steel, carbon steel, aluminum) and the wall thickness is determined by the abrasiveness of the material and the needs of the application (e.g., food grade). |

| Bends and Elbows | These are wear-prone regions, especially in dilute phase systems. Long-radius bends are used to reduce impact and friction. For very abrasive materials, reinforced or specially designed wear-resistant bends are required. |

| Diverter Valves | These valves, including slide gate valves, allow the material stream to be directed to various discharge points without stopping the system. |

The Final Stop: Cyclones, Filters, and Hoppers

The conveyed material should be effectively separated at the end of the line from the conveying air.

| Separation Technique | Description |

| Filter Receivers (Baghouses) | The most widespread separation technique, often part of a larger dust collection system. Air with material is introduced into the filter receivers, and the air is filtered through filter media (bags or cartridges) as the material particles are deposited on the outside. The filters are then cleaned by pulses of compressed air, and the material falls into the hopper below. |

| Cyclone Separators | Separate the larger particles in the air stream using centrifugal force. They are commonly employed as a pre-separator in front of a filter receiver to minimize the dust load on the filters. |

| Receiving Hoppers/Silos | This is the last point where the collected material is stored and then discharged to the next process. |

Evaluating the Pros and Cons: Is Pneumatic Conveying Right for You?

There is no universal solution to technology. An engineering evaluation of pneumatic conveying must be conducted with a sober view of the advantages and disadvantages of technology when compared to mechanical conveying.

Advantages:

- Total Containment: The closed system is arguably the strongest feature of the system. It avoids dust emissions into the plant, which safeguards the health of the employees and avoids cross-contamination of products. It also shields the material against external contaminants.

- Routing Flexibility: Pipelines may be laid virtually anywhere; horizontally, vertically, and around existing obstacles. This gives it some degree of design freedom that cannot be achieved with most mechanical conveyors.

- Low Maintenance: There are few moving parts in the conveying path (particularly in comparison to screw or chain conveyors), which means that the maintenance needs are minimized.

- Small Footprint: A pipeline takes up a lot of floor space less than a similar belt or bucket elevators, making the most of plant real estate.

Disadvantages:

- Energy Intensive: It is energy intensive to move large amounts of air, particularly at high pressure. Pneumatic systems may require more horsepower per ton of conveyed material than mechanical conveying systems.

- Product Degradation Potential: As mentioned, the high velocity of dilute phase systems may cause damage to delicate or friable materials.

- Abrasive Wear: Abrasive substances may result in severe wear on pipelines, especially at bends, which results in maintenance expenses and possible system leakage.

- Low Capacity: In very high-throughput applications (e.g., mining or bulk port terminals), mechanical systems such as belt conveyors can have higher capacities for heavier materials.

- Blockage Risk: The system may be blocked due to improper design or operation, and this may take a lot of time to clear.

Critical Applications Across Industries

The flexibility of pneumatic conveying is seen in the fact that it is used in almost all industrial industries dealing with dry bulk solids.

- Food Processing: Pneumatic systems are used to transport food products such as flour and sugar in a commercial bakery, coffee beans and snack foods, where the hygiene standards are very high.

- Plastics and Chemicals: Plastic pellets are transported between railcars and silos and between silos and extruders. Dry powders in chemical plants are transported out of reactors to packaging lines, and containment is a safety concern.

- Pharmaceuticals: Pneumatic systems are sealed in an industry that requires the highest level of purity, and the sealed nature of the pneumatic systems is necessary to transfer active pharmaceutical ingredients (APIs) and excipients without contamination.

- Minerals and Construction: Abrasive substances such as cement, fly ash, sand, and lime are usually processed with strong, wear-resistant dense phase systems, which reduce the wear of the pipes and dust pollution.

- Agriculture: Grains, seeds and animal feeds are loaded, unloaded and transferred in large storage and processing plants.

Each of these industries benefits from the adaptability and efficiency of pneumatic conveying systems, showcasing their critical role in modern manufacturing and processing.

The Core of a Reliable System: The Critical Role of High-Performance Automation Parts

A pneumatic conveying system is a dynamic and challenging environment. The distinction between a system that performs perfectly over years and one that is marred with frequent downtime and inefficiency is often a matter of the quality and engineering of the individual components. These automation components are not just accessories, but they are essential to the process, and they regulate the metering, direction, and flow of the whole system. Precision-engineered components are not an investment, they are a direct investment in uptime, performance, and long-term profitability, whether from a single source supplier or multiple vendors.

Beyond the Basics: How Precision Components Solve Common Conveying Pain Points

Off-the-shelf, standard components can be used to perform simple tasks, but they do not always solve the nagging issues that engineers encounter in the real world. Here is where precision engineering comes in:

- Abrasion: A typical rotary valve that is used in the abrasive cement will soon wear away the rotor tips and the housing, losing the pressure seal, efficiency and eventually fail. A precision valve will, however, be made of hardened materials (such as Ni-Hard or Stellite), have adjustable or replaceable tips, and include design features such as V-trough inlets to shield the rotor, which will greatly increase its service life.

- Contamination: A poorly designed diverter valve may contain internal ledges or crevices where material may accumulate, resulting in batch cross-contamination. It is designed with a high-performance, sanitary-grade valve that is easy to clean (CIP/COP), and has smooth surfaces and no dead spaces, which guarantees purity of the product.

- Inefficiency and Downtime: The loss of the pressure seal in a worn rotary airlock is a major cause of inefficiency, as the blower has to work harder to counteract the loss of air. Close-tolerance machined parts ensure that critical seal, which consumes less energy. Moreover, parts that can be removed and serviced quickly, such as slide-out rails to replace filters cages, transform a multi-hour service into a quick, easy task, maximizing system uptime.

Hebai-Omch’s Advantage: Engineering Parts for Maximum Uptime and Performance

- Maximize Uptime: Reliable Quality, Delivered Fast

- Simplify Sourcing: 3,000+ Models from One Partner

- Built to Last: Lower Your Maintenance & Replacement Costs

- Tailored Solutions to Win Your Market

In the dynamic world of industrial automation, the reliability and performance of your systems rely heavily on the quality of the components used. Hebai-Omch has built its reputation on delivering high-performance automation parts, specifically designed to minimize downtime and maximize efficiency. With a commitment to top-tier engineering and precision manufacturing, Hebai-Omch ensures that its products, such as cylinders, pneumatic valves, and FRL units, meet the most stringent quality standards. By using certified components that comply with ISO 9001, CE, CCC, and ROHS certifications, they offer a direct investment in your business’s uptime and long-term profitability. The company’s advanced production capabilities and a robust global supply chain allow for fast, reliable deliveries, ensuring minimal operational disruptions.

Beyond simply providing components, Hebai-Omch excels in offering flexible customization options tailored to your specific needs. From stroke length and bore diameter to material selection, these products are precision-engineered to meet the demanding requirements of industries like automobile manufacturing, food and pharmaceutical production, and electronics. The company’s strong focus on innovation ensures that their solutions not only meet current market needs but also anticipate future challenges, giving you a competitive edge. By offering reliable, high-quality products and seamless integration with your systems, Hebai-Omch helps you reduce operational costs while improving overall system performance.

What sets Hebai-Omch apart from other suppliers is its unwavering commitment to providing outstanding pre-sales and after-sales support. With over 20 years of experience, their expert team is available 24/7 to offer technical support and resolve any issues quickly, minimizing potential downtime. Additionally, Hebai-Omch’s use of cutting-edge automation and a global logistics network enables same-day shipping for in-stock items. This ensures fast, efficient order handling and on-time delivery, whether locally or internationally. By choosing Hebai-Omch, you’re not just buying components—you’re partnering with a supplier dedicated to your success through precision, reliability, and continuous innovation.

Selecting the Right Parts for Your Application: A Manufacturer’s Perspective

We, as engineers and manufacturers, recommend that one should not only look at the initial price tag when specifying components. The total cost of ownership is the real cost of a part. Consider these factors:

- Duty Cycle: Will the component be 24/7 or intermittent? A continuous-duty application requires a more strongly constructed part.

- Material Characteristics: Do not simply think of abrasiveness. Is the material corrosive? Sticky? Temperature sensitive? Every feature might demand a certain material of construction or design aspect.

- Maintenance Accessibility: How accessible is the component to inspect, clean, and service? A properly designed component may save thousands of labor expenses during its life.

It is important to collaborate with a component manufacturer that is aware of these subtleties. We can offer the application knowledge to assist you in choosing not only a part, but the correct part to your particular problem.

Conclusion: Partnering for a Smarter Pneumatic Conveying Solution

Pneumatic conveying is a powerful and versatile technology, a cornerstone of modern industrial processing. We have seen that its successful implementation rests on a solid understanding of its core principles, a careful evaluation of its different forms, and a strategic selection of its coresystem components. While the overall system design provides the blueprint, it is the quality and precision of the individual automation parts that ultimately determine its reliability, efficiency, and longevity.

A system burdened with poorly specified or under-engineered components will never reach its full potential. It will suffer from unnecessary wear, costly downtime, and inefficient energy use. Conversely, a system built with high-performance, application-specific parts becomes a seamless, robust, and highly profitable asset.

Your material handling system is too critical to be compromised. If you are looking to optimize an existing line or design a new system for maximum performance, the conversation must include the quality of its components. We invite you to connect with our team of application engineers. Let us help you build a smarter pneumatic conveying solution, one precision-engineered part at a time.