Each day, there is a huge and unending stream of raw materials that cross our oceans, forming the backbone of global supply chains. It is a movement, which is not in gallons, but in millions of metric tons, a continuous supply of grains, ores, and crude oil, which is the foundation of the modern industrial society. These bulk commodities, which are loaded loose in the huge holds of giant ships, have one unglamorous name: bulk cargo. They are the silent titans of global trade, whose trip between the source and the destination is a miracle of size, logistics, and engineering. This guide will bring you into the depth of the world of these vital commodities, not just what they are and how they move, but also the secrets of automation that are so vital to their efficient bulk cargo transportation.

A Foundational Definition: What Exactly is Bulk Cargo?

In its simplest form, bulk cargo is characterized by what it does not have: individual packaging. Any commodity that is transported in large quantities without packaging is this specific type of cargo. These goods are not boxed, bagged, or bottled to sell as smaller items like those you would find in a supermarket shelf. They are instead emptied, pumped or loaded directly into the hold of a ship, barge, railroad car or truck.

These goods are homogenous and fungible, i.e. any single particle of a particular shipment is, practically speaking, identical to any other. Some dry bulk cargo can be defined as a mass of relatively small solids. A grain of wheat at the top of a silo is identical to a grain of wheat at the bottom; a drop of crude oil is no different than the millions of barrels it rides with. This consistency is essential to its treatment.

Therefore, this commodity cargo is not quantified in units but by mass (metric tons, deadweight tons) or large volumes (cubic meters, barrels). When a ship is chartered to transport iron ore, the amount is defined in the contract, such as 150,000 metric tons, which is a single, huge consignment loaded without any containers or wrappings in between. This is the most cost-effective mode for the transportation of goods worldwide, and it constitutes the initial and most important connection in the global economy.

The Two Primary Types of Bulk Cargo

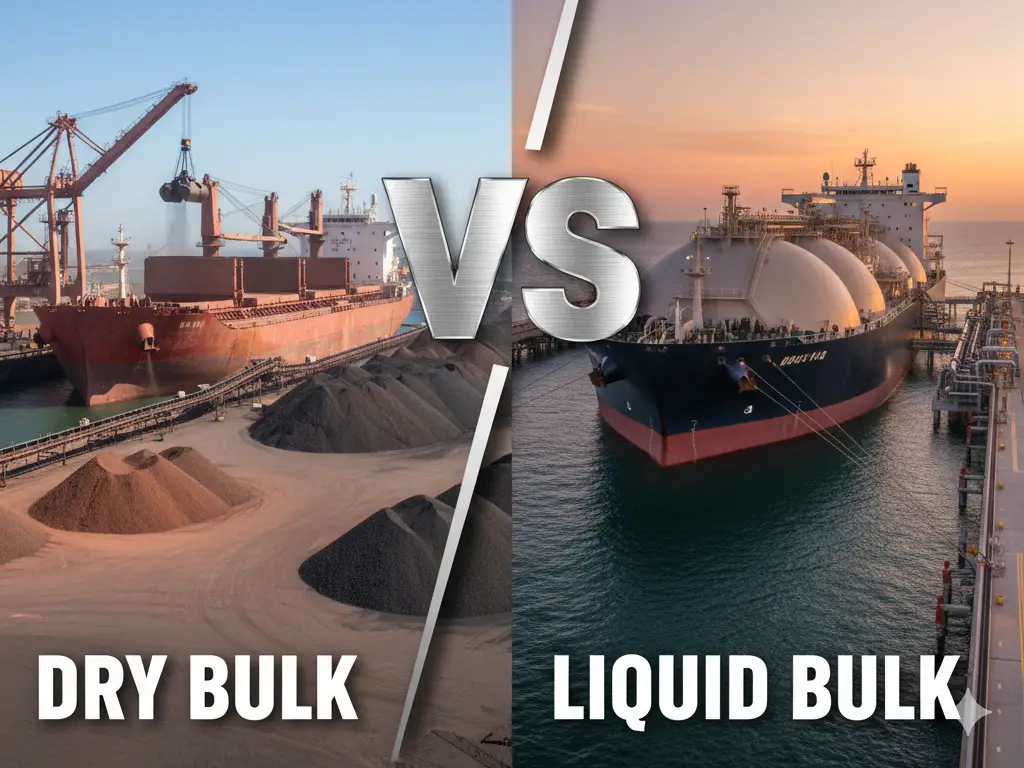

Although the idea of unpackaged goods is straightforward, the world of bulk cargo is widely split into two different categories depending on the physical condition of the goods. Understanding the different types of bulk cargo is key. This basic classification, covering both dry cargo and liquid, determines the type of bulk cargo vessel to be used, the handling equipment to be used and the safety measures to be observed.

Dry Bulk: Moving the World’s Raw Materials

Dry bulk commodities are the solid, granular or particulate substances that nourish our factories and construct our cities. They are a great variety of dry bulk goods, which can be further divided into major and minor bulks according to the volume of trade in the world. Among the most notable bulk materials, there are:

- Iron Ore and Pig Iron: The main raw materials in the production of steel. They are basic building blocks to our urban landscapes and infrastructure, shipped in large amounts out of mining centers to industrial powerhouses.

- Coal: An important source of energy for power generation and a major ingredient in steel production (coking coal). Its transportation over the seas is a direct indication of the energy demand in the world.

- Grains: This group consists of wheat, corn (maize), soybeans, rice, and barley. These are the agricultural staples that form the basis of the world food supply, as they are transported out of breadbasket countries to the rest of the world.

- Cement and Clinker: These are the binding materials of concrete, and these dusty powders are the backbone of the construction industry everywhere.

- Fertilizers: Phosphates, potash, and nitrates are exported to agricultural areas in large quantities to enrich the soil and increase crop production, which is a crucial factor in world food security.

- Other Minor Bulks: The list goes on to include sugar, salt, scrap metal, and other mineral sands, all of which serve particular industries and consumer demands.

Liquid Bulk: Transporting Essential Fluids

Liquid bulk cargorefers to any commodity that is in liquid form and is pumpable. These goods are transported using special tanker vessels that have segregated tanks to maintain purity and avoid dangerous reactions. The energy industry is the most prevalent in this category, but there is a broad spectrum of other essential fluids.

- Crude Oil: The major source of energy in the world. Millions of barrels of crude oil are transported by supertankers to oil refineries around the world, before eventually being distributed by methods including a tanker truck.

- Petroleum Products: After refining, the products of crude oil, including gasoline, diesel, jet fuel, and heating oil, are shipped as individual products in smaller, specialized product tankers.

- Liquefied Natural Gas (LNG)and Liquefied Petroleum Gas (LPG): Natural gas and petroleum gases are liquefied by cryogenic cooling to significantly decrease their volume of transportation. This involves very advanced, insulated ships that are meant to keep temperatures as low as -162 C (-260 F).

- Chemicals: A huge variety of industrial chemicals, including ammonia and sulfuric acid, are transported in special chemical tankers with several stainless steel or coated tanks to transport corrosive and hazardous substances safely.

- Edible Oils: The transport of edible fats and plant oils such as palm oil and sunflower oil are also managed in bulk tankers and are used in the food processing sector worldwide.

Key Distinctions: Bulk vs. Break Bulk vs. Containerized Cargo

The terminology is confusing to new entrants in the logistics world. It is important to know the distinction between bulk, break bulk and containerized cargobecause these three modes of shipping are fundamentally different. While bulk cargo is loose, break bulk cargo consists of goods that are handled individually, often in smaller quantities than a full bulk shipment. This is different from both bulk and general cargo that is containerized. Both are determined by the character of the cargo itself.

| Characteristic | Bulk Cargo | Break Bulk Cargo | Containerized Cargo |

| Form | Loose, unpackaged, homogenous (e.g., grain, coal, oil) | Non-standardized, individually handled items (e.g., machinery, steel beams, crated goods) | Goods of any type packed into standard TEU or FEU containers |

| Handling | Pumped, conveyed, or grabbed by specialized equipment | Lifted individually by cranes using slings, nets, or hooks | Lifted by specialized container cranes (spreaders) |

| Unit of Measure | Mass (tons) or Volume (cubic meters) | Per piece, per ton, or per project | Per container (e.g., per TEU – Twenty-foot Equivalent Unit) |

| Vessel Type | Bulk Carriers, Tankers | General Cargo Ships, Multi-Purpose Vessels | Container Ships |

| Port Operations | Requires specialized terminals with silos, tanks, and conveyors | Labor-intensive, requires large open storage areas (laydown yards) | Highly standardized and automated container terminals |

Simply put, when the cargo is flowable or scoopable, it is bulk. When it is one, big item such as a yacht or a blade of a wind turbine, it is break bulk. When it is packed into a large, standardized metal box, it is containerized.

The Journey of Bulk Cargo: Specialized Vessels and Port Infrastructure

It is not an easy task to transport millions of tons of unpackaged material across the seas. Bulk cargoshipping is based on a highly specialized ecosystem that is aimed at one thing: the maximization of efficiency on a large scale. This system starts with the vessels themselves, including the huge Panamax and Capesize bulk carriers or supertankers. These vessels are designed with specific trade routes in mind, so that they can carry huge amounts of material, be it dry goods such as coal or grain, or liquid cargo such as oil. But the voyage does not stop when these ships arrive at port.

When bulk carriers reach a port, they are greeted by equally specialized infrastructure that is used to process their cargo. A special bulk terminal is necessary to help in the efficient unloading of goods. In this case, very synchronized equipment systems are involved. Giant gantry cranes with huge clamshell grabs or shovel buckets can pick up to 85 tons of coal in a single scoop, and bulk materials can be transferred between ship and shore quickly. In the meantime, giant ship-loaders, fitted with long conveyor belts, allow rapid and efficient loading of grain at thousands of tons per hour.

In the case of liquid cargo, the unloading is also highly advanced. The ship is linked to large tank farms by a complex network of pipes and pumps that allow the transfer of liquids. This system, which works with a high degree of coordination, is the essential linkage between land and sea. Having such specialized vessels and port facilities, the bulk cargo shipping industry makes sure that the materials are transported efficiently all over the world, which preconditions even more significant progress in automation and technology in the future.

The Unseen Force: How Automation Powers Bulk Cargo Handling

At Hebai-Omch, we understand that behind every smooth bulk cargo operation lies a robust and precise automation system. Bulk cargo handling, which includes materials like grains, coal, and cement, requires maximum efficiency and precision. This is where automation—powered by our advanced pneumatic products—plays a crucial role. Our products ensure that every mechanical movement in your operation is driven by precision, increasing the overall speed and efficiency of loading and unloading processes.

Thanks to our 37 years of experience in the automation industry, we are equipped to provide you with reliable, high-performance solutions that minimize downtime, reduce operational costs, and enhance your throughput. Our cylinders, valves, and actuators are engineered to meet ISO 6431 standards. They are designed to withstand even the most demanding environments, ensuring consistent performance under pressure.

Why Pneumatic Parts are the Unsung Heroes in Bulk Handling

In bulk cargo handling, pneumatic systems are the backbone that ensures seamless operations. Pneumatic cylinders, valves, and actuators are indispensable in controlling material flow, reducing delays, and improving efficiency. The rapid response times of our products allow for precise regulation of material handling, helping you achieve faster loading and unloading cycles.

Beyond performance, pneumatic systems also address safety concerns in hazardous environments, such as those filled with dust or chemicals. For example, the explosion-proof, non-sparking features of our pneumatic systems make them ideal for handling materials like grains or cement, where dust explosions pose a serious threat. Our cylinders also come with impressive IP ratings of IP65, IP67, and IP68, offering excellent dust and water resistance for long-term reliability even in harsh environments.

Reliability and Maintenance: The Hebai-Omch Advantage

Pneumatic components from Hebai-Omch are not only built for performance but also designed for longevity. With a typical lifespan ranging from 3 million to 10 million cycles, our cylinders maintain exceptional reliability in demanding conditions. Whether in ports exposed to high salt, humidity, or dust, or in other tough environments, our components are engineered to perform with minimal downtime and maintenance.

We take pride in the robust, quality-controlled manufacturing processes that ensure our pneumatic products meet ISO 9001 standards and other industry certifications, including CE, CCC, and ROHS. As a result, our clients benefit from a cost-effective and efficient solution that maximizes uptime, minimizes maintenance costs, and helps them stay ahead in the competitive bulk cargo handling industry.

Common Advantages and Inherent Challenges of Shipping in Bulk

The prevalence of bulk shipping is based on a distinct and strong advantage, yet it does not lack its own set of distinct challenges, including strict storage requirements. The first is the economy of scale that is unmatched. The cost per ton of transportation of bulk commodities is much less than that of any other mode of shipping by removing packaging and maximizing cargo capacity. Nevertheless, this approach has a number of difficulties:

- Product Loss and Degradation: Spillage, dust or residue in the hold during loading, transit and discharge will result in a certain degree of product loss. The improper handling of cargo, especially sensitive organic materials, can also lead to contamination or degradation.

- Environmental Risk: A major pollution incident, such as an oil spill, poses a significant environmental impact. The entire shipping industry must adhere to a strict international code of practice to mitigate these risks. For solid bulk cargoes, this is the IMSBC Code (International Maritime Solid Bulk Cargoes Code), which provides detailed transport guidelines. Crews often use an IMSBC code pocket guide and review MSDS sheets, which list cargo details in an alphabetical index, to prevent accidents.

- Infrastructure Dependency: Bulk shipping is completely reliant on the presence of specialized ports and terminals at both ends of the trip. This inflexibility may restrict trade routes.

- Logistical Complexity: The logistics of bringing a huge ship with storage capacity on the land side and onward transportation is a complicated logistical riddle that must have careful planning.

It is in mitigating these challenges that operational excellence and investment in reliable technology, especially robust automation systems, really come into their own.

The Future is Smarter: Bulk Cargo in the Age of Automation

The basic principles of bulk shippingmight be eternal, yet the industry is about to experience a technological revolution. The future of bulk cargo handling is admittedly smarter, pushed by the incorporation of sophisticated automation, IoT, and data analytics.

Terminals are turning into smart ports, with all equipment being interconnected. When this data is analyzed, it can be used to predict when a component may fail and make maintenance a predictive science. This development will result in a new generation of bulk logistics, which is not only faster but also much safer and more environmentally friendly. With an increase in the global demand of raw materials, the role of intelligent automation, which is driven by trusted technologies such as pneumatics, will only be more central to the continued operation of the global economy. For further research, there are many useful websites dedicated to the shipping industry.

After understanding the intricate world of bulk cargo and the automation that powers it, you may be looking to enhance the efficiency and reliability of your own material handling systems. We invite you to explore our portfolio of high-performance pneumatic solutions, designed to deliver power and precision for your most demanding applications.