Introduction: Why Automation is Reshipping the Modern Supply Chain

For decades, the global supply chainhas been working on a predictable, albeit strained rhythm. Goods were transferred, timetables were adhered to, and the complex game of logistics, though complicated, was essentially controlled by human labor and the developed procedure. That period of predictability is unquestionably gone. The modern supply chain is a volatile landscape. Customer demands have increased to the point where next-day (or even same-day) delivery is the standard. The instability of networks that are constructed on efficiency as the primary criterion has been shown by supply chain disruptions, such as pandemics and geopolitical changes, exposing businesses to potential disruptions.

In this new world, it is no longer a strategic decision to stick to the old systems and manual processes; it is a statement of weakness. The bottlenecks in supply chain efficiency, the constant threat of human error, and the inability to respond to sudden demand spikes are not small operational challenges. They are core competitiveness and survival threats. The pressure is so great and the reaction cannot be gradual.

It is against this backdrop that supply chain automation has ceased being a visionary idea and become a practical, urgent need. It is a radical re-invention of the sourcing, storage, movement, and delivery of goods. This guide is meant to act as a point of entry into this transformative field. We will transition to the principles of a practical implementation framework that will give you the clarity to navigate this necessary transformation in your business processes.

What Exactly Is Supply Chain Automation?

Simply put, supply chain automation is the tactical use of automation technologies to perform and control the routine activities and supply chain processes of the flow of goods between the supplier and the customer with the least amount of human intervention. This includes warehouse automation, where advanced systems handle tasks such as sorting, picking, packing, and inventory management to minimize errors and accelerate throughput. It is not the replacement of the whole workforce with robots, but the enhancement of human capacity. The aim is to establish a more efficient, reliable and data-driven ecosystem in which human talent is not wasted on repetitive tasks and error-prone work but rather on more strategic work in the form of oversight, analysis and exception handling.

Imagine a digital nervous system being injected into the physical body of your supply chain operations. This system links the processes that are not related, such as inventory management and order processing to the warehouse picking and transportation logistics, into a self-regulating whole. It uses a combination of automation tools, including advanced automation software and smart equipment, to do the heavy lifting, both literally and figuratively. The outcome is a supply chain that is capable of working faster, more accurately and 24/7.

Core Concept vs. Traditional Supply Chain Management

*This video will tell us what supply chain management is.

In order to understand the full effect of process automation, it is helpful to compare it with the old model that has been ruling logistics over the generations. It is not a difference of degree, but of kind.

The conventional supply chain management is essentially reactive and man-intensive. It is based on paper trails, spreadsheets, and manual data entry. Pick lists are walked by warehouse employees over miles of aisles, inventory is counted manually, and decisions are frequently made using past data and gut feelings. The flow of information is in discrete steps that are usually delayed. A customer order could be printed, physically transported to the warehouse floor, picked and packed manually, and then inputted into a different shipping system. Every handoff is a possible failure point—a possible delay, a misplaced document, or a mere human error. The whole system is limited by the physical constraints and working hours of its human workers.

Anautomated supply chain, in its turn, is proactive and data-driven. It works on a live, integrated data stream. Once a customer makes an order, the system handles it immediately. The Warehouse Management System (WMS) finds the item, sends an autonomous mobile robot (AMR)—a type of autonomous vehicles—to pick it up, and automatically changes the inventory levels in real-time. All this is coordinated by software and all the steps are recorded and can be seen throughout the organization. Predictive analyticsand real-time conditions are used to make strategic decisions, which enables the system to predict bottlenecks or reroute shipments before they occur. It is a system constructed not to stand still, but to move.

| Aspect | Traditional Supply Chain Management | Core Concept: Automated Supply Chain |

| Approach | Reactive and man-intensive. | Proactive and data-driven. |

| Technology | Based on paper trails, spreadsheets, and manual data entry. | Works on a live, integrated data stream with real-time coordination. |

| Order Handling | Orders are processed manually. A customer order could be printed and physically transported to the warehouse. | Once a customer places an order, the system handles it immediately using integrated software and systems. |

| Inventory Management | Inventory is counted manually, and decisions are frequently based on past data and human intuition. | Inventory levels are updated automatically in real-time, using Warehouse Management Systems (WMS) and autonomous mobile robots (AMRs). |

| Information Flow | Information flow is in discrete steps and usually delayed. | The flow of information is integrated and instantaneous, with all steps recorded and visible throughout the organization. |

| Decision Making | Decisions are made using past data and gut feelings, often leading to delays or mistakes. | Predictive analytics and real-time data are used to make informed strategic decisions. |

| Error Risks | Every handoff or transfer is a potential point of failure, such as delays, misplaced documents, or human error. | Risk of errors is minimized through automation and real-time monitoring, with predictive capabilities reducing bottlenecks. |

| Workforce | Dependent on human workers’ physical constraints and working hours. | The system operates continuously without the limitations of human working hours, using automated systems. |

| System Dynamics | The system is largely static, constrained by manual processes and human limitations. | The system is dynamic, constantly moving and adapting to real-time conditions, avoiding bottlenecks and optimizing flow. |

The Transformative Benefits: Why Your Business Can’t Afford to Wait

Adoptingsupply chain automationis not just an operational improvement, but a business strategy that provides compounding returns. The value proposition is evident and multifaceted and it affects all aspects, including the balance sheet and customer loyalty. Here are the key benefits of supply chain automation.

- Radical Efficiency and Productivity Improvements: Systems can work 24/7 without exhaustion by automating repetitive tasks such as data entry, goods retrieval, and sorting. This enables a significantly greater number of orders to be handled within the same time, directly proportional to throughput and operational capacity, but not directly proportional to headcount.

- Major Cost Savings: The economic gains are high. Automation decreases the reliance on human labor, which alleviates the effects of labor shortages and rising labor costs. More to the point, it reduces the excessive operational costs of mistakes, such as mis-picks, wrong deliveries, and spoiled products, which involve costly reverse logistics and, in most cases, lost sales. These cost savings are a primary driver for adoption.

- Maximization of Accuracy: Automated systems perform supply chain tasks with a degree of accuracy that cannot be maintained by humans, leading to fewer errors. Barcode scanners, vision systems and robotics make sure that the correct product is selected, packed and delivered to the correct customer, each and every time. This degree of precision, which can be over 99.9%, removes expensive errors and creates customer confidence.

- Improved Supply Chain Visibility: The elimination of the black box problem in logistics is one of the strongest benefits of automation. Managers can have a real-time, end-to-end perspective of their entire supply chain throughinternet of things (IoT) sensors and integrated software. They are aware of the location of inventory, shipments in transit, and equipment performance, which allows much smarter and proactive management.

- Better Customer Satisfaction and Retention: All these benefits eventually lead to an improved customer experience. Reduced processing time, almost flawless accuracy of orders, and proactive communication regarding the status of delivery are directly translated into increased customer satisfaction. This high level of customer service is a strong differentiator and a source of loyalty in a competitive market.

Key Technologies Driving the Automation Revolution

The strength ofsupply chain automation is achieved by a synergistic integration of digital intelligence and physical implementation. These new technologies are the building blocks of a modern and resilient logistics operation.

The Digital Layer (The “Brains”): This includes the software and data platforms that coordinate the whole process.

- Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP): These are the base software platforms. A contemporary WMS is the air traffic controller of the warehouse that controls inventory, orders, and labor. The ERP combines this information with the larger business processes such as finance and procurement processes.

- Artificial Intelligence (AI) and Machine Learning (ML): Artificial intelligence is the optimization engine. It is applied to advanced demand forecasting, transportation route optimization to save fuel and time (reducing carbon emissions), and predictive analytics that can anticipate possible equipment failures before they occur. Newer forms like generative AI are beginning to process vast data sets to further refine these models.

- Internet of Things (IoT): IoT is the network of sensors installed on pallets, vehicles, and machinery. This includes radio frequency identification (RFID) tags for enhanced inventory tracking. These sensors deliver the real-time data stream—location, temperature, vibration—that drives the whole system, and gives the granular visibility required to make intelligent decisions.

The Physical Layer (The “Brawn”): This consists of machinery and robotics that do physical work.

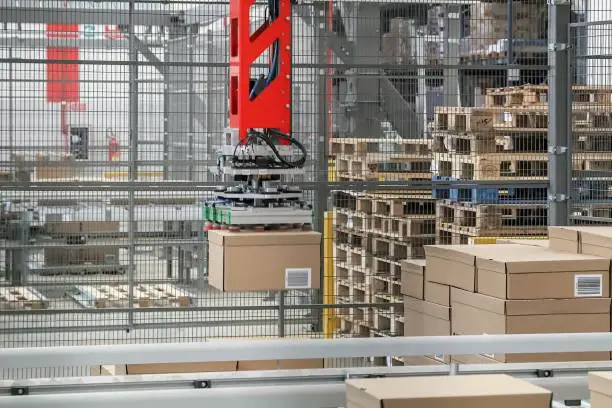

- Robotics and Robotic Arms: Stationary robotic arms are applied in repetitive tasks such as palletizing, depalletizing and packing with tireless accuracy, ensuring high quality control over the production process.

- Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs): The workhorses of the modern warehouse. AGVs are usually guided by predetermined routes (such as magnetic tape), whereas the more sophisticated AMRs are guided by sensors and AI to move shelves and pallets to human operators or other automated stations.

- Automated Storage and Retrieval Systems (AS/RS): These are high-density, vertical storage systems that have automated cranes or shuttles that store and retrieve totes or pallets at a high rate. They drastically enhance storage density and retrieval efficiency, helping to maintain optimal stock levels.

The Unsung Heroes: Why High-Quality Automation Parts Are Your Most Critical Investment

As smart software serves as the brain and the amazing robotic arms are the visible muscles of supply chain automation, a very important question is often forgotten: What is the hardworking backbone of the system? What makes all the commands of the software come to physical motion perfectly, not once, but millions of times?

The solution is in the unsung heroes of automation: the high-quality components and parts that tirelessly labor within each machine. Most companies commit the error of concentrating on the large-scale equipment and software packages and considering the smaller parts—the cylinders, valves, sensors, and grippers—as commodities. This is a fatal mistake that can ruin the whole investment.

How Component Failure Creates a Cascade of Hidden Costs

One low-quality part, costing only $50, can bring a multi-million dollar automated system to a crawl. The actual cost of component failure is not the replacement cost; it is the disastrous chain of unseen costs that spreads across the whole operation. This is the dark side of a highly integrated system: a single weak link can destroy the entire chain.

- First of all is downtime. In a manual process, when one employee is sluggish, the others can usually absorb the slack. With a highly synchronized automated system, the breakdown of one important part on a conveyor or robotic arm can stop the whole line. Each minute of this unplanned downtime is a direct loss of revenue and productivity.

- Second are the rising maintenance expenses. Components of low grade wear out easily and need frequent servicing and replacement. This increases the labor costs of technicians and the number of spare parts. What appeared to be a cost-saving strategy during the first purchase turns out to be a recurring and unpredictable operational cost that gradually kills your ROI.

- Lastly, there is the gradual poison of performance degradation. A damaged or inaccurate component might not break down but can cause a reduction in precision. A gripper that fails to hold or a sorter that activates a fraction of a second too late may result in product damage, mis-sorts and wrong orders, which is reintroducing the very errors that the automation was designed to remove.

A Prime Example: The Power and Precision of Industrial-Grade Pneumatics

We can take an example of one of the most basic technologies of physical automation: pneumatics. Pneumatic systems are powered by compressed air and are used to perform some of the most important, high-speed operations in a warehouse or factory, including various use cases:

| Capability | Description | Purpose & Application |

| Blazing-Fast Sorting | Diverting packages on a conveyor belt with millisecond accuracy. | Enables efficient sorting of packages, improving speed and precision in the logistics process. |

| Dependable Grasping | Selecting and placing products, including delicate raw materials, with consistent force and precision. | Ensures the safe handling of products, especially fragile materials, minimizing damage and maintaining product quality. |

| Heavy-Duty Lifting | Moving heavy loads with ease and safety, crucial for the order fulfillment process. | Facilitates the movement of large and heavy items, improving efficiency and reducing the risk of injury during manual handling. |

Speed, power and durability are known to be the characteristics of pneumatic systems, however, what makes the difference between a system that works and a system that propels remarkable efficiency is the quality of the components. Pneumatic cylinders used in industry, such as those in the industrial grade, have better seals to avoid air leakage to save more energy, strong materials to resist wear and tear, and accurate engineering to ensure the same performance after millions of cycles. At Hebai-Omch, we are aware that in automation, the least considered factors are not the advanced robots or the advanced software, but the seemingly insignificant pneumatic components. Quite on the contrary, they are a policy against inefficiency and downtime, which is not expensive. When you select trusted pneumatic parts, you are guaranteed that your automation system will work as advertised not only in the short term but also over the years to come, and the tiniest parts are the real protectors of the stability and profitability of the supply chain.

Pneumatics are a perfect example of how quality parts can resolve the most important issues in the contemporary industries. Our pneumatic solutions provide unparalleled performance in high-speed sorting which requires pinpoint precision to robotic assembly which needs agile and dependable gripping. Our cylinders, valves, and accessories are certified to ISO 9001 standards and have CE, CCC, and ROHS certifications, designed to last long and be resilient, which significantly lowers the maintenance costs of our products in comparison to those of lower grade. Our products maintain a constant production and optimize resources with lifespans of 3 to 10 million cycles, better noise reduction and energy-efficient operation. Combine all this with our customizable nature, where we provide stroke lengths, bore diameter, and material choices, and we enable businesses to optimize inventory, improve operational efficiency, and achieve long-term competitiveness. In the case of Hebai-Omch, pneumatics excellence is not only about components, but also about keeping your business ahead.

Your 5-Step Roadmap to Successful Implementation

The process of embarking on an automation project may be overwhelming. The key to risk mitigation and a successful outcome is a structured, phased approach that follows industry best practices.

- Evaluate and Find Opportunities: Start with a critical evaluation of what you are doing. Trace your workflows through to the end and determine the main bottlenecks, high error rates, or physically demanding and repetitive tasks. Use this information to identify the complex processes in which automation will have the most significant initial effect.

- Establish Specific Goals and KPIs: What, exactly, do you want to accomplish? Do not accept such goals as vague as improving efficiency. Identify measurable Key Performance Indicators (KPIs) to take your supply chain operations to the next level.

Examples: Reduce order picking time by 30 percent, increase order accuracy to 99.8 percent, or reduce labor costs in the packing department by 15 percent.

- Select the Right Technology and Partners: Depending on your goals, study the technologies that suit your specific needs. AS/RS is best suited to high-density storage, whereas AMRs are flexible in picking. Most importantly, screen your technology suppliers, including your automation platform provider, and implementation partners. Seek established track records, industry experience and willingness to provide post-implementation support.

- Manage Change and Train Your Team: Automation is a people issue as much as it is a technology issue. Effective change management is critical. Share the vision with your employees and supply chain professionals, making them understand how the technology will support them, not displace them. Invest in extensive training to reskill employees for new positions in system oversight, maintenance, and management.

- Start Small, Measure, and Scale: Do not be tempted to automate everything at once. Start with a pilot project in a controlled location. This will enable you to pilot technology, optimize processes and prove a definite ROI with reduced risk. Measure success rigorously using the KPIs identified in step two. After proving the pilot, you can create a staged rollout strategy to expand the solution to the facility or network.

Common Pitfalls to Avoid on Your Automation Journey

Even the most promising automation projects may fail unless approached carefully. The initial move towards success is to know the pitfalls that are likely to derail your efforts. Lack of a clear business case is one of the greatest errors. Automationis a recipe for failure when it is invested in without specifying the business problem it is meant to solve, and without a reasonable payback period. Each automation project must be linked to a specific business objective to support the investment.

The other error is that process optimization should not be overlooked prior to automation. Automation of a bad process does not fix the problem, it just makes the problem quicker. First, it is necessary tostreamline and optimize processes, making sure that workflows are efficient and do not violate regulations. This base will not only enhance the efficiency of the technology but also enhance the overall success of the automation project.

Lastly, failurecan also be caused by underestimating the complexity of integration and neglecting the human factor. New automation systems should be able to integrate with the current platforms such as WMS or ERP without causing data silos and operational interruptions. Also, it is essential to engage frontline staff in the process of making them buy-in. When employees perceive technology as a threat or a burden, it may cause resistance and affect the success of the project. By overcoming these obstacles, you can make the process of automation more likely to succeed.

Conclusion: Taking Your First Step Towards an Automated Future

At Hebai-Omch, we realize that in the current industrialized world, the stability and automation of supply chains are the main factors to remain competitive. We have 37 years of experience and are still working on optimization of our manufacturing and logistics, which guarantees efficient production, reliable delivery, and high quality control. Supported by ISO certifications and internationally recognized standards, we assist our customers to reduce downtime and increase efficiency and profitability.

Automation of the supply chain is more than ever. It does not only reduce delivery cycles but also makes sure that the necessary parts are at the right place at the right time, keeping production lines operating at their optimum level. We have flexible, durable, and internationally compliant cylinders, valves, tubing, and fittings that are used in automotive, electronics, food, and pharmaceutical industries. When we collaborate, we will have access to stable and reliable technical support and 24/7 after sales services.

The future of automation is no longer a choice, but a necessity. It is time to review and modernize your supply chain. We can collaborate to make your operations efficient, reliable, and innovative. The first step to success is to select the appropriate partner and quality components– and that step starts with Hebai-Omch.