Introduction to Pneumatic Cylinders: The Driving Force of Automation

Pneumatic cylinders are important in the modern industry where efficiency and precisionare key factors. They transform compressed air into linear movement and are used as actuators in many industrial automation processes. These are activities like the movement of robotic arms in assembly lines or the lifting of heavy parts in construction machines. Pneumatic cylinders play a crucial role in manufacturing, packaging, and material handling processes. Pneumatic cylinders come in various forms and each has certain features that make it suitable to a certain application. It is necessary to understand the differences between them to design efficient, cost-effective, and operationally-specific systems. This paper aims at highlighting the major differences between single acting and double acting cylinders in order to make informed choices in automation design.

Unpacking Single-Acting Pneumatic Cylinders

Think of something simple, direct, a punch, a clamp, a push. In these applications, the single acting cylinder frequently comes on stage. It is the more straightforward of the two types of cylinder, and it is efficient in its straightforwardness. This simplicity and efficiency stem from its underlying mechanism.

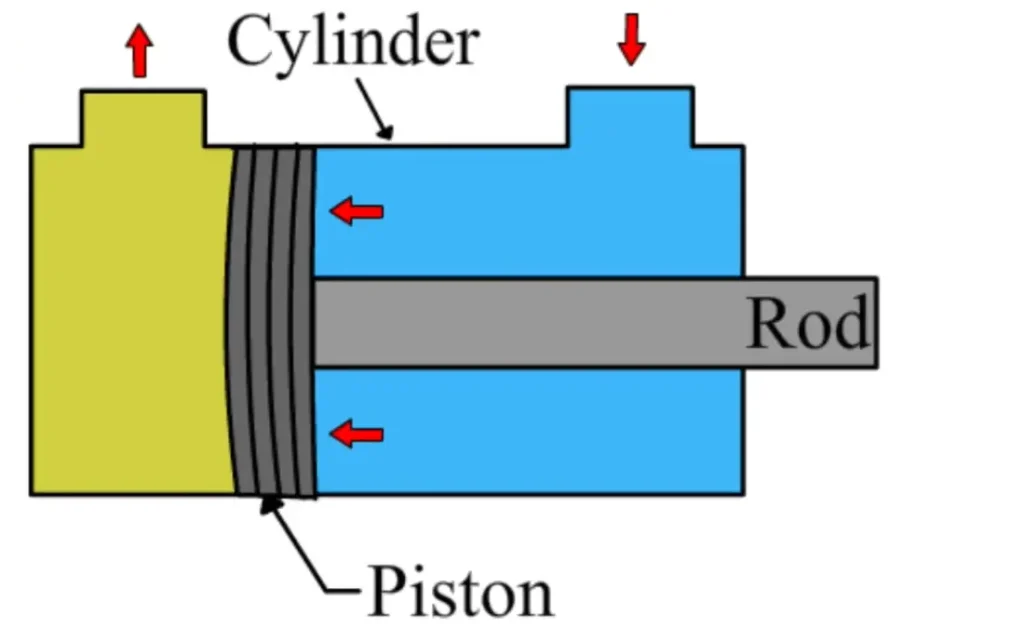

The mechanism of a single acting pneumatic cylinder is simple. Only one side of the piston is subjected to compressed air, and the piston moves in one direction only – this is called the working stroke. After the release of the air pressure, the piston should go back to its original position. This back movement is not driven by air but by an external force. This force is usually supplied by an internal spring which was compressed in the working stroke and then expands to push the piston rod back. Instead, gravity or the weight of the load can help in returning. Since the cylinder operates in one direction only under air pressure, it only needs a single port to operate. This cylinder design inherently offers simplicity.

Key Characteristics and Common Applications

Single acting cylinders are especially useful in many applications where ease of use, cost-effectiveness and reliability are paramount. They are suitable for most industrial applications due to their intrinsic advantages, including small size and reduced air consumption.

Key Characteristics

- Simplicity: Single acting cylinders are simpler in design because they have fewer internal parts.

- Compact Size: These cylinders are smaller and lighter in weight because of the fewer components.

- Cost-Effective: Single acting cylinders are less expensive to manufacture and buy due to the simpler design and fewer parts.

- Installation: They are generally simpler to install, needing less piping and less complicated installations.

- Reduced Air Consumption: Single acting cylinders consume air in one direction of movement only, which reduces air consumption as compared to the double acting cylinders.

- Reliable: They are simple and therefore reliable in certain applications since there are fewer parts that may fail.

Single acting cylinders are simple but perfectly fit in various applications. They are often applied in clamping, ejecting, and in simple lifting or pressing operations, where the backstroke need not be powered or finely controlled. They are a fundamental part of most automated systems due to their dependability in such functions.

Exploring Double-Acting Pneumatic Cylinders

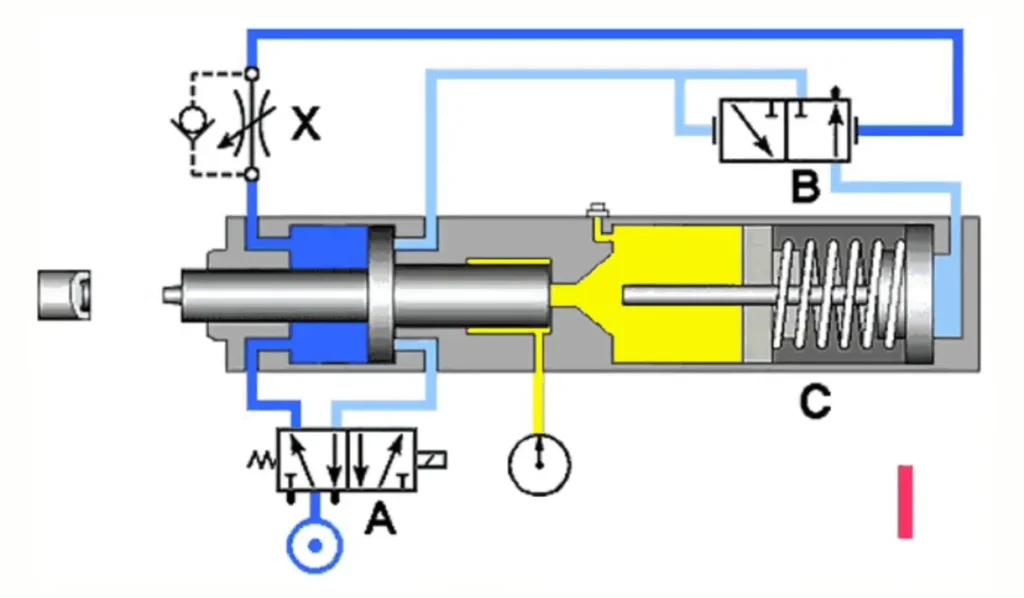

When your application needs delicate control and thrust in both directions: pushing and pulling, extending and retracting, the solution of choice is the double acting pneumatic cylinder. It is the more general-purpose workhorse, two-way linear motion dynamic and precise. To attain this degree of control and flexibility, the mechanism of a double acting cylinder is a minor modification of that of a single acting cylinder, the chief difference being:

The principle of operation of a double acting cylinder is similar to that of its single acting counterpart, except that there is one significant difference; the air pressure is exerted on both sides of the piston. This means that the compressed air moves the piston rod in one direction (extension) and then by redirecting the air to the other port, the piston rod is moved in the other direction (retraction). This is two-way control through two airports, one on each side of the piston. The active driving of both strokes gives unsurpassed control of the movement, speed and thrust of the cylinder, making it far more versatile. One of the ports may be called the front port (to extend) and the other the top port (to retract) based on the mounting orientation with respect to the end of the cylinder.

Versatile Applications and Performance Advantages

The double acting pneumatic cylinder is characterized by its outstanding versatility and performance and is therefore suitable in applications that demand high precision and dependable movement in both directions. It has many benefits and the scope of its applications is extensive.

Key Advantages

- Precise Control: Delivers consistent force throughout the extension and retraction strokes, allowing precise positioning and manipulation.

- Independent Speed Control: The speed of extension and retraction can be independently controlled by airflow through each port, which is essential to synchronized operations.

- Flexibility in Use: Can be used in a variety of applications that involve two-way movement, including lifting, pressing, or repositioning.

- Constant Force: The double acting cylinder has constant force during both strokes and is therefore suitable in applications where reliability and stability is required.

- Strong and Adaptable: It can apply force in both directions, making it ideal to use in tensioning, stretching, or compressing applications in manufacturing.

This fine control and flexibility provides a massive scope of applications that cannot be matched by single acting cylinders. In industrial automation and robotics, double acting cylinders are everywhere, powering complicated movements such as robotic arms or opening and closing industrial doors. They also form parts of material handling, packaging machinery and most manufacturing processes whereprecision and two-way movements are essential to the production of uniform products. They use more compressed air and are usually larger and more complex, but the improved performance and control they offer can be worth the trade-offs in challenging applications in a wide variety of industries.

Head-to-Head: A Comprehensive Comparison

*This video introduces the basic operational similarities and differences between single-acting and double-acting cylinders.

It is just the starting point to understand the single acting and the double acting cylinders individually. In order to make a hesitation-free decision, it is necessary to directly compare the most important functional and structural points. A side-by-side comparison is shown in the table below that can be used to understand the area where each type of cylinder scores and where it can fail.

| Aspect | Single Acting Cylinder | Double Acting Cylinder |

| Force & Direction | Exerts force in only one direction; return relies on spring or external force | Exerts force in both extension and retraction directions |

| Control over Movement | Limited control on return stroke; less precision | Full control over both strokes; ideal for applications requiring precise motion control |

| Speed Regulation | Return speed may be inconsistent and hard to regulate | Speed in both directions can be finely tuned via air throttling |

| Air Consumption | Uses compressed air for one stroke only; return is air-free | Consumes air in both strokes; enables smoother operation and optimized cycle times |

| Structural Complexity | Simple design with one port; often includes a return spring | More complex, with two ports and no return spring |

| Installation Requirements | Easier to install; minimal plumbing needed | Requires more complex piping and valve arrangements |

| Size & Footprint | More compact; suitable for limited space | Generally larger due to dual ports and absence of internal spring |

| Maintenance Needs | Fewer moving parts; easier maintenance when no spring is involved | Slightly higher maintenance but better long-term reliability and environmental protection |

| Best Suited For | Simple, space-constrained, or low-duty applications with one-way actuation needs | High-precision, high-duty, or bidirectional tasks where controlled retraction is essential |

Although in comparison, the single acting cylinders are simple, smaller, and they may use less air, the double acting cylinder gives its subtle control and directionality of power needed in challenging and dynamic situations. The reason can always be due to the preferences of your system, be it less is more and convenience or perfection and speed.

Selecting the Perfect Cylinder for Your Needs

The decision between a single acting and a double acting pneumatic cylinder is not a matter of which is better, but which is more appropriate to a particular job. It is a matter of matching the capabilities of the cylinder with the requirements of your application. Choosing the right cylinder is paramount.

When your operation needs mostly force in one direction (e.g. pushing, clamping, punching), and the return stroke can be accomplished by a return spring, gravity, or an existing load, a single acting cylinder is usually the more rational and cost-effective solution. Its simplicity means that it is cheaper to buy, uses less air consumption to power its stroke and may be easier to maintain. Consider the basic automated doors that open using air and close using a return spring, or a mechanism that throws out a part after processing. These are typical applications for this type of cylinder.

But when your application requires precise control and thrust in both directions, extending and retracting, pushing and pulling, or positioning with accuracy, then a double acting cylinder is essential. The double acting design will be of great benefit in industrial automation applications such as robotic arm movements, complex material handling systems where the objects must be pushed and pulled on conveyor belts, or any situation where controlled acceleration and deceleration in both directions is required. Although they are more expensive to purchase and use more compressed air, their flexibility, controllability, and capability of performing a wide range of applications and a wide variety of industries make them the obvious choice in sophisticated automation. Never forget the total lifecycle cost, which is the energy cost, maintenance cost, and the effect of precision and cycle time on the overall productivity.

Why Choose Hebai-Omch for Your Pneumatic Cylinder Needs?

At Hebai-Omch, we bring nearly four decades of expertise to the field of pneumatic cylinders and industrial automation. Since our founding in 1986, we’ve been committed to delivering products known for their durability,precision, and superior sealing performance. Our cylinders meet stringent international standards, including ISO, CE, and RoHS certifications, ensuring long-lasting performance and reliable operation across diverse applications. We take pride in helping our customers achieve greater efficiency and reliability in their automation systems.

We understand that every project has unique requirements, which is why we offer highly flexible customization options. From stroke lengths ranging from 10 mm to 2000 mm, bore diameters from Ø12 mm to Ø320 mm, and a selection of premium materials—including aluminum alloy, stainless steel, and carbon steel—we ensure our cylinders meet even the most demanding needs. Whether you operate in the fields of industrial automation, automotive, food and beverage, or packaging, Hebai-Omch provides tailored pneumatic solutions that enhance productivity and performance.

Our commitment doesn’t stop at product quality—we also strive to deliver exceptional service and support. With a robust inventory across multiple warehouses in China, we offer same-day shipping for in-stock items, helping you minimize lead times. Our expert technical team is available 24/7 to provide guidance and troubleshooting, and we offer comprehensiveOEM manufacturing, CNC machining, and secondary processing services. At Hebai-Omch, we don’t just supply pneumatic cylinders—we partner with you to ensure your success in every project.

Conclusion: Powering Your Progress with the Right Pneumatic Cylinder

The realm of automation is vast and intricate, but at its heart lie fundamental components like the pneumatic cylinder. The choice between a single acting and a double acting cylinder is a pivotal decision that can significantly influence the efficiency, precision, and cost-effectiveness of your automated systems. Single acting cylinders offer simplicity and economy for unidirectional tasks, acting as reliable workhorses for straightforward applications. Double acting cylinders, with their bidirectional control and versatile force application, are the powerhouses for complex, high-precision movements.

Understanding their distinct operational principles, structural differences, and application suitability is not just theoretical knowledge; it’s the foundation for intelligent cylinder design and optimal performance. By carefully assessing your specific needs for force, control, speed, and precision, you can make an informed decision that elevates your automation capabilities.And when you decide to do business with us at Hebai-Omch, you are not only receiving a high quality product tailored to your exact requirements, but you are also getting a reliable partner who will be there to help you succeed at every turn. We think the correct cylinder can propel the next step in your automation process, and we are here to assist in making it happen.