Introduction: The Unseen Force Behind Modern Automation

Pneumatics, a key branch of fluid power technology, is both basic and advanced, and it is necessary for developing efficient, reliable, and cost-effective robotic solutions in modern automation. To engineers, designers and system integrators, knowledge of pneumatic systems and pneumatic actuation is essential in coming up with effective robotic solutions for various industrial applications.

This guide is intended to be a comprehensive guide. We are going to learn the basic principles of compressed air in motion, examine the elements that make a complete system, and compare pneumatic systems with electric drives and hydraulic systems. We will also talk about real-life applications and issues, and the future of robotics. At the end of it, you will be well versed with the pneumatic drive system and will be able to work with it.

How Does a Pneumatic Drive System in Robotics Actually Work?

*This video explains the pneumatic drive system: definition, components, working principle, its use in robots, and pros and cons.

A pneumatic system operates through energy conversion. The principle is easy but the process needs accurate parts that interact in a robotic setting. In order to see how it works, we shall follow the conversion of electrical current into mechanical motion, step by step.

From Compressed Air to Motion: The Core Principle Explained

The journey from electricity to motion starts with the air compressor, the heart of any pneumatic system that relies on compressed air. The compressor draws air and compresses it with the help of an electric motor to a smaller volume. This compression imparts potential energy to the air. This highly compressed air is then held in a tank, which is ready to be released when required.

When the robot is commanded to do something, a signal is transmitted to a control valve, which discharges a certain quantity of compressed air. The air flows through tubing and fittings and arrives at the actuator. Inside the actuator, this expanding air forces apiston, and the energy of the stored air is transformed into mechanical movement. The effect of this action is that the robot performs various tasks like lifting, clamping, or pressing components, which are common in material handling. When the job is done, the air is released out of the actuator and the piston goes back to its initial position.

The Anatomy of a Pneumatic System: Core Components You Must Know

The successful operation of a pneumatic system relies on several critical components, each playing a vital role. A failure in any part can disrupt the system’s function.

| Component | Description |

| Air Preparation Unit (FRL) | This unit ensures the quality of the compressed air. It consists of three devices: the filter, which removes particles, moisture, and potential contamination; the regulator, which controls and stabilizes the air pressure; and the lubricator (in some systems), which adds oil to the air to lubricate moving parts. |

| Directional Control Valves | These valves direct the flow of compressed air. They receive electrical signals and open or close to control the flow of air to the actuator. Depending on the design, they can be simple on/off switches or more advanced valves that modulate the flow for finer control. |

| Pneumatic Actuators | These are the components that convert the energy from compressed air into mechanical work. The most common types are pneumatic cylinders, which use pistons to create linear motion (a pushing or pulling force). |

| Pneumatic Grippers | Pneumatic grippers use smaller cylinders to open and close with precision. |

| Pneumatic Motors | For applications requiring circular movement, pneumatic motors can convert airflow into rotary motion, delivering specific levels of torque. |

| Sensors, Tubing, and Fittings | Tubing delivers compressed air throughout the system, while fittings connect the various components. Sensors provide feedback, indicating the position of actuators to ensure the correct actions occur. |

The Core Debate: Pneumatic vs. Electric Drives in Robotics

In the world of driving technology for robotic systems, engineers often face a critical decision: choosing between pneumatic, electric, and even hydraulic systems (which use hydraulic fluid instead of air). There is no universal solution; finding the right fit depends on factors like power, precision, cost, and the operating environment. It is important to understand the unique advantages and weaknesses of each system in order to make an informed decision.

When Pneumatics Wins: Power, Speed, and Robustness

Pneumatic systems are best suited in applications that demand strength, speed and durability. They have the following advantages:

- High Power Density: Pneumatic cylinders are relatively lightweight and can generate more force for their size and weight than electric actuators, which enables compact designs that can perform heavy duty work.

- Speed: Pneumatic actuators are quick, especially in simple applications such as full extension or retraction, and are therefore suited to high-speed applications such as pick-and-place.

- Simplicity and Durability: Pneumatic cylinders are simple mechanically, and have fewer moving parts. This simplicity makes them robust, able to withstand harsh environments with little wear and requiring only regular maintenance.

- Environmental Resilience: Pneumatic systems are resilient to environmental contamination like dust, humidity, or extreme temperatures, and can be used in environments where electronics may not work.

- Cost-Effectiveness: Pneumatic parts are generally cheaper than their electric equivalents, and can save a lot of money in large systems with numerous actuators.

Where Electric Excels: Precision, Control, and Efficiency

Electric systems are superior in precision, control, and energy efficiency applications. They have the following advantages:

- Precision and Control: Electric systems, often using servo motors, provide exceptionally precise control over positioning, velocity, and acceleration, and are therefore suited to applications that need fine control.

- Energy Efficiency: Electric systems are more costly to install, but are more energy efficient than pneumatic systems, which lose energy in the form of compression and air leaks.

- Low Noise: Electric systems are less noisy than pneumatic systems and thus more appropriate in noise sensitive areas.

- Reduced Infrastructure:Electric motors only need an electrical connection, but pneumatic systems rely on compressors, pipes, and other parts that must be maintained.

Comparison Table: Pneumatics vs. Electric Actuators

| Dimension | Pneumatics | Electric |

|---|---|---|

| Power Density | High: Lightweight cylinders deliver strong force for size/weight → compact & heavy-duty capable | Lower: Needs larger/heavier components for equivalent force |

| Speed | Very fast in simple extend/retract tasks → ideal for pick-and-place | Fast but less extreme in simple motions; more focused on controllable speed |

| Precision & Control | Limited accuracy, simple on/off style control | Excellent precision in position, velocity, acceleration (servo-driven) |

| Simplicity & Durability | Simple mechanics, few moving parts, robust, low maintenance | More complex, electronic components sensitive to harsh conditions |

| Environmental Resilience | Works in dust, humidity, extreme temps → where electronics may fail | More vulnerable to contamination, temperature, humidity |

| Energy Efficiency | Lower: energy lost in compression & leaks | Higher: efficient use of electricity, lower running cost |

| Noise | Noisy (airflow, valve clicks) | Quiet, better for noise-sensitive environments |

| Infrastructure | Requires compressors, pipes, valves → ongoing maintenance | Needs only electrical connection, simpler setup |

| Cost | Lower upfront & per-part cost → big savings in large systems | Higher upfront cost, but lower long-term energy cost |

Real-World Applications: Where Pneumatic Systems Shine

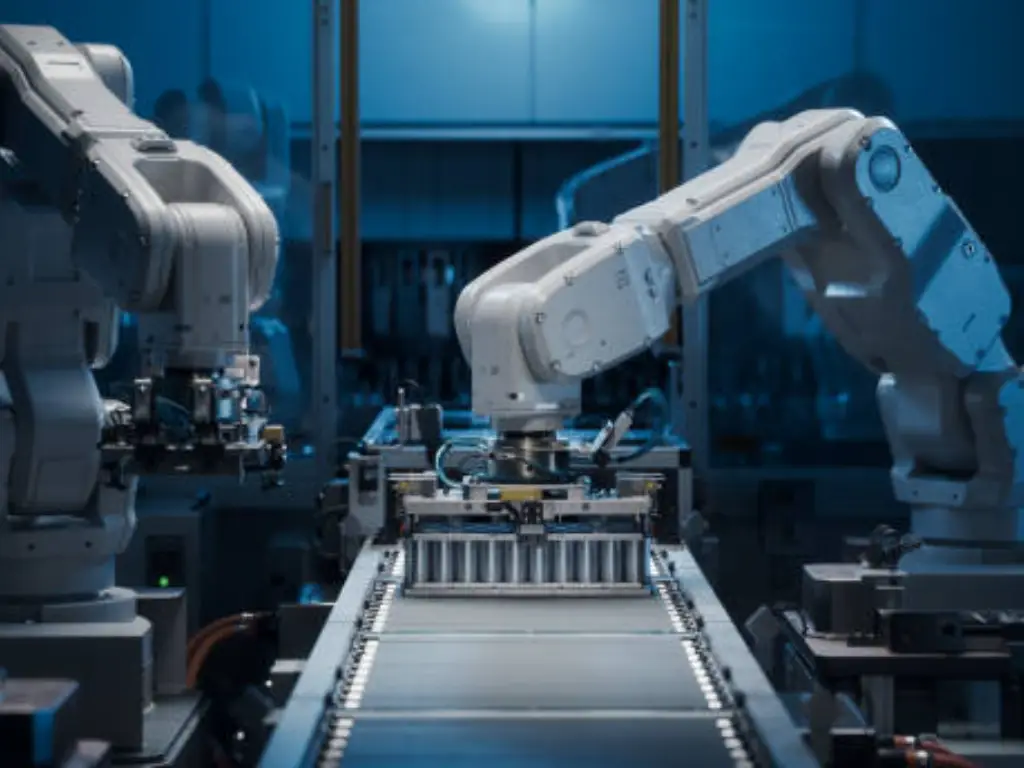

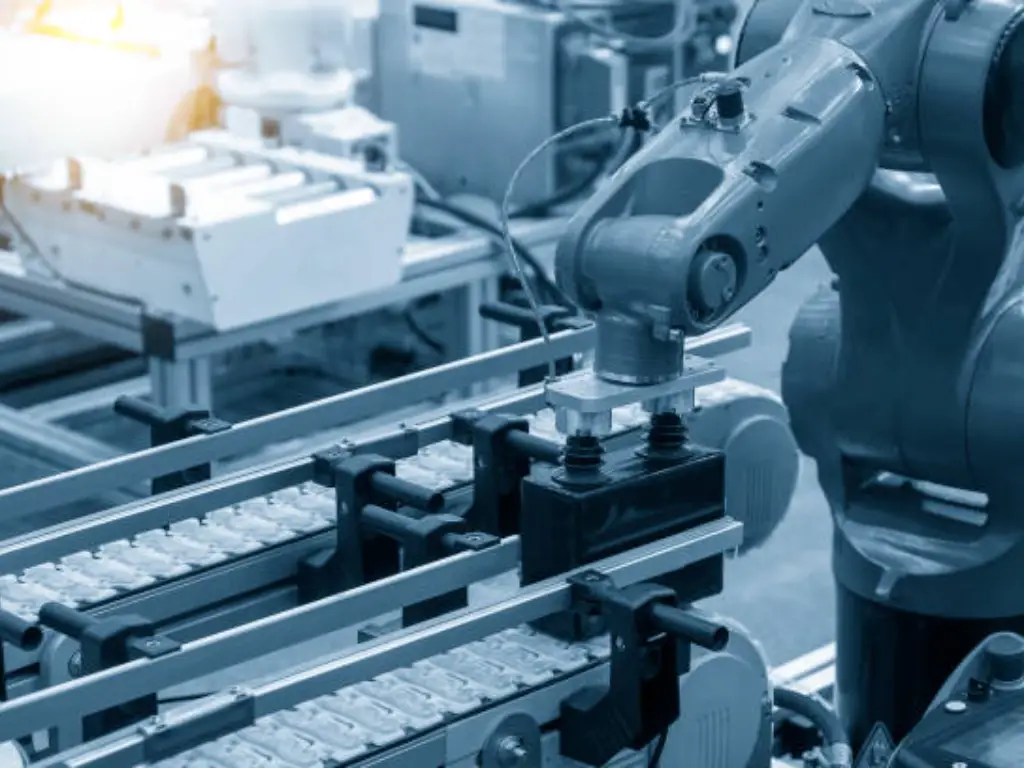

Pneumatic systems are popular across various manufacturing processes and industries like industrial automation, electronics manufacturing, and soft robotics, where their advantages are the most useful.

Pneumatic grippers and clamps are found in industrial automation, such as gripping body panels on automotive assembly lines or placing components in electronics packaging. Pneumatic systems are also good at high-speed operations, and can cycle quickly, boosting productivity.

Pneumatics is flexible and compliant, which is desirable in soft robotics to manipulate fragile items such as fruit or textiles without damaging them.

Pneumatics also suits special applications such as paint spray booths or food processing plants, where requirements like being explosion-proof or maintaining high levels of cleanliness are paramount.

Common Challenges in Pneumatic Systems (And How to Overcome Them)

Pneumatic systems are highly appreciated due to their low cost and ease of use. However, they have a number of typical problems.

Energy efficiency is one of the major problems. Compressing air is a very energy-intensive process and even small leaks in the system can lead to large losses. To overcome this, frequent inspection and maintenance is necessary. Efficiency can also be enhanced by the use of high-performance compressors, better sealing techniques and the use of monitoring systems to identify and minimize leaks in a short time.

The other difficulty is complexity of control. Air is compressible, so it may be challenging to obtain accurate and stable control. This complicates the ability to satisfy the requirements of high-level automation processes. To address this shortcoming, industries are increasingly resorting to advanced valve technology and advanced control algorithms. These solutions allow better control of air pressure and flow, making it more responsive and better performing.

Finally, there is noise and maintenance. Pneumatic systems are known to produce significant noise when in use and the quality of air can increase wear and result in downtime and expensive repairs. A clear grasp of what is pneumatics allows companies to apply these remedies more effectively. The best remedies are to incorporate noise control, proper air filtration and drying, and preventive maintenance programs. In this way, companies not only prolong the life of equipment but also ensure the stable and effective work of the system.

Beyond Components: How Our Advanced Pneumatic Products Elevate Your Robotics

- Maximize Uptime: Reliable Quality, Delivered Fast

- Simplify Sourcing: 3,000+ Models from One Partner

- Built to Last: Lower Your Maintenance & Replacement Costs

- Tailored Solutions to Win Your Market

Understanding these challenges is the first step, but choosing the right partner provides the solution. At Hebai-Omch, we don’t just manufacture pneumatic products; we engineer solutions that directly address these industry pain points. By integrating our advanced FRL Units, pneumatic cylinders, and air preparation accessories, we help you optimize the performance and longevity of your robotic systems while reducing operational costs.

Energy Efficiency: Cutting Costs with Advanced Air Preparation Solutions

Energy efficiency is essential to reducing costs in modern automation systems. Our Energy-Efficient FRL Units and Smart Air Management Modules are designed to automatically detect and seal air leaks, significantly cutting down on energy wastage. By ensuring that air preparation is optimized with precise pressure regulation and filtration, our products help you reduce operational expenses and maximize system efficiency. With Hebai-Omch, your robotic systems can work smarter, not harder.

Precision Control: The Perfect Balance Between Pneumatic Power and Electric Accuracy

Achieving optimal control in robotics requires both power and precision. Our High-Precision Proportional Valves and Servo-Pneumatic Systems combine the best of both worlds—delivering powerful pneumatic force while integrating the exactness of electric control. This synergy allows your robotic systems to operate with enhanced flexibility, responsiveness, and precision. Whether it’s for automated production lines or automotive manufacturing, our solutions ensure you get reliable performance with minimal energy consumption.

Noise & Maintenance: Creating a Quieter, More Reliable Environment

Noise and maintenance concerns can hinder productivity. Our Integrated Silencers and Long-Life Valves and Cylinders are engineered to significantly reduce operational noise, ensuring a quieter working environment for your robots. The modular design of our components also makes maintenance easier and more cost-effective, reducing downtime and extending the service life of your equipment. With Hebai-Omch, you not only get advanced performance but also the reliability and durability that keep your operations running smoothly.

The Future is Here: Smart Pneumatics and the Soft Robotics Revolution

Smart pneumatics is bringing a new age of Industry 4.0 integration. As the IO-Link technology has emerged, pneumatic components are no longer passive elements but smart systems that can perform predictive maintenance, self-diagnosis, and remote monitoring. With the integration of digital sensors and real-time data connectivity, companies can maximize energy consumption, minimize downtime, and predict system failures before they happen, making pneumatics a key facilitator of smart manufacturing.

Meanwhile, the frontier of soft robotics is broadening the horizons of pneumatic applications. The interaction of robots with the world is being revolutionized by advanced designs like pneumatic artificial muscles and bio-inspired actuators. Whether it is medical rehabilitation equipment that needs safe and gentle contact, service robots and flexible automation in logistics, soft pneumatics is making robotics more adaptable, human-centered, and versatile, which is why it is firmly established at the forefront of the next industrial revolution.

Conclusion: Making the Right Choice for Your Robotic Application

Pneumatic systems are powerful, fast, and durable, and therefore are very effective in certain situations, whereas electric systems are precise and energy efficient. All three drive types, hydraulic, pneumatic, and electric, have their own benefits and drawbacks, and the trick is to match the technology to the requirements of your application.

We hope that this guide has given you the knowledge to assess and apply pneumatic drive systems successfully in your robotic applications. When you are ready to learn how advanced pneumatics can streamline your operations, call our engineering team today to discuss your needs in a free consultation.