- FAQs

- Catalog

- Blogs

Standard Cylinders

- Home

- Pneumatic Cylinders

- Standard Cylinders

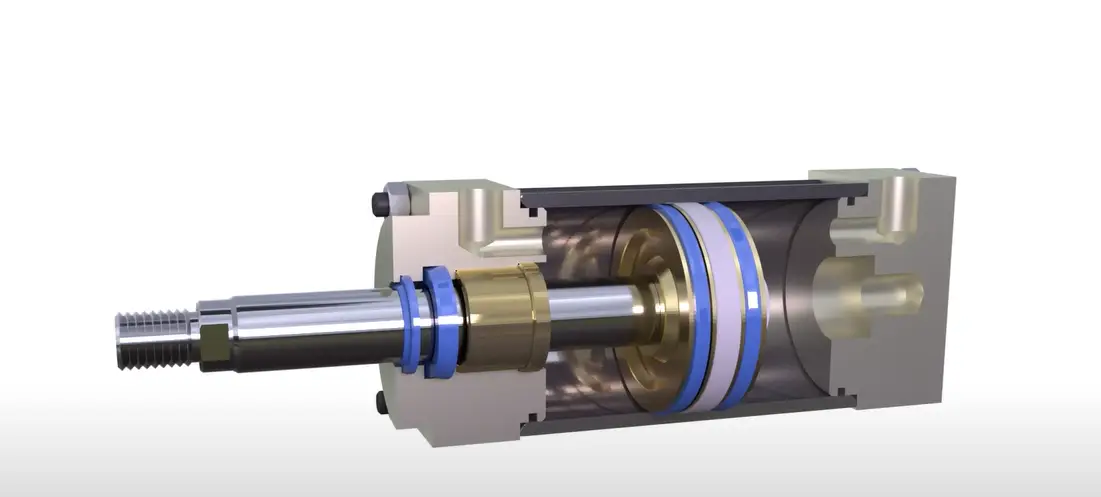

Hebai-Omch standard cylinders excel in durability, precision, and sealing performance, ensuring stable and efficient operation even in high-demand automation systems. With over 37 years of engineering expertise, our products support quick assembly, easy replacement, and are widely compatible across various industries and applications. Our products align with the highest standards in the market in terms of quality and performance, helping you enhance efficiency while also offering you higher profit margins and returns. We currently offer a range of standard cylinders that meet the following specifications:

As one of China’s leading pneumatic cylinder manufacturers, Hebai-Omch delivers high-quality products with advanced technology and strict quality control. Our standard cylinders follow global standards, ensuring compatibility and flexibility for those looking to buy automation parts. Trusted by over 72,000 clients worldwide, we help enhance performance, ensure reliability, and simplify system integration.

Your trusted standard cylinder manufacturer, offering a complete series with multiple mounting options—including FA (front flange), FB (rear flange), LB (foot mount), CA/CB (clevis), and TC/TCM (trunnion)—to meet your diverse automation and system needs.

1

As your industrial automation parts supplier, we offer cylinders conforming to ISO 15552, ISO 6432, tie-rod industry standards, and compact de facto standards, giving you the flexibility you need. From custom strokes to special seals, we tailor solutions for a perfect fit.

A

B

C

D

A

B

C

D

Specify the exact stroke length you need. Eliminate design compromises and make your machine more compact and efficient.

Customize rod ends and fittings for seamless, plug-and-play installation. Increase reliability and get your equipment running faster.

Choose specialized seals for extreme heat, cold, or chemical exposure. Drastically extend cylinder life and minimize costly downtime.

Select from stainless steel, aluminum, and more. Ensure your cylinder withstands corrosion, meets industry standards, or is lightweight.

More than just a standard cylinder factory, we are your partner in innovation, ready to engineer the exact cylinder you need.

| Parameter | Standard Range | Custom |

|---|---|---|

| Stroke | 10 mm to 2000 mm | Longer or shorter strokes available |

| Piston Rod | Single/Double Rod, Male/Female Thread, Non-rotating, Extended/Shortened | Special threading, coatings, or anti-corrosion treatments available |

| Materials Sections | Aluminum Alloy, Stainless Steel | Special alloys available upon request |

| Seals | NBR (Standard), FKM (High-Temperature), PU (High-Wear), Low-Friction | Specialty seals for ultra-low friction, or food-grade compliance |

| Working Environment | Standard, Clean Room (ISO Class), Chemical-Resistant | Custom environments and protection levels |

As leading standard cylinder suppliers, we provide robust solutions to boost your productivity. Our cylinders deliver the speed and precision essential for enhancing efficiency and ensuring reliable performance in your most demanding applications.

For perfect vehicle bodies, precision is everything. Our cylinders provide the powerful and reliable clamping and positioning force your fixtures need, guaranteeing every component is held exactly in place for flawless welding and assembly, every single time.

In your industry, gentle precision is key. Our cylinders provide the smooth, controlled motion needed to lift, position, and press delicate PCBs and components without causing damage, ensuring the high quality and integrity of your electronic products.

1

As a trusted industrial automation parts supplier, we deliver high-performance, reliable cylinders designed to meet global standards, ensuring longevity, precision, and efficiency across various industrial applications.

Tested for durability, our cylinders deliver over 50 million trouble-free cycles to keep your lines running longer with less downtime.

Delivers up to 480N at 0.6 MPa (Ø32) — ensuring powerful, consistent motion even in demanding load applications.

Internal leakage ≤ 0.02 MPa/min, external leakage eliminated — minimizing energy loss and maximizing system stability.

Reliable at over 5Hz actuation frequency, perfect for high-speed automation lines and precision cycles.

As a trusted automation parts supplier, we provide you with high-quality standard cylinders and fast, reliable delivery to ensure your systems run smoothly.

Find Your Product

Provide us with the make and model of the product you need, and our team can locate the correct item or a suitable replacement.

Same Day Shipping

We have multiple warehouses in China with a substantial product inventory. If you require in-stock items, we can ship to you as quickly as the same day.

We offer industrial automation products, custom manufacturing, and aftermarket parts, backed by our 8000㎡ factory and a capacity of over 20 million units annually. This ensures exceptional quality and scalability for broader market reach.

After-sale Support

Our industrial automation products come with comprehensive after-sales support, so you can focus on marketing and selling while we take care of everything else.

Secondary Processing

Upgrade your standard cylinders with high-precision machining, enhanced surface treatments for corrosion resistance, optimized sealing performance, and rigorous functional testing. Ensure exceptional durability, reliability, and performance for demanding pneumatic applications.

Expert Technical Support

Hebai-Omch’s team of expert technicians has decades of experience in Standard Cylinders manufacturing and provides on-time, comprehensive customer support for any inquiries related to our products.

Our standard pneumatic cylinders are engineered for excellence, fully compliant with strict ISO standards and certified by CE and RoHS. These certifications highlight our commitment to quality, safety, and efficiency—giving you full confidence when purchasing pneumatic cylinders online for global applications.

A: Choosing the correct cylinder size is essential for optimal performance. First, determine the required push or pull force using the formula: Force = Pressure × Area. To ensure reliable operation, it’s recommended to select a cylinder with a force rating at least 50% higher than your calculated requirement.

Next, focus on the bore size, as it directly affects the cylinder’s force output. Based on your calculated force and the available system pressure, choose an appropriate bore size. Common options include 32mm, 40mm, 50mm, 63mm, 80mm, and 100mm.

Finally, determine the necessary stroke length, which is the distance the piston must travel. Measure the exact movement needed by your load to ensure accurate sizing. In summary: calculate the required force, select a matching bore size, and then specify the stroke length. If you need help, our technical team is ready to support you.

A single-acting cylinder is a pneumatic component that uses compressed air to move in only one direction (usually to extend). It retracts automatically using an internal spring or an external load when the air pressure is released. With only one air port, it is simpler, more cost-effective, and energy-efficient, making it ideal for one-way tasks like clamping, ejecting, and positioning.

A: Choose a Single-Acting Cylinder if you need simple, one-way operations, such as clamping, pushing, or ejecting. It saves energy, using about 50% less air, and has a lower system cost due to its simpler design with fewer components. The cylinder automatically returns via a spring when the air is cut off, which is great for safety and provides a default return position.

Choose a Double-Acting Cylinder if your application requires force in both directions. It provides powerful pushing and pulling capabilities, with precise control over both the extension and retraction strokes. This type of cylinder is ideal for longer strokes and more complex movements because it isn’t limited by an internal spring.

In short, for simple “push and release” tasks, go for a single-acting cylinder. For more powerful “push and pull” operations with precise control, choose a double-acting cylinder. Your decision depends on the specific requirements of your application.

A: One common issue in pneumatic cylinders is crawling or jerky motion, which is typically caused by low air pressure or a side load due to misalignment between the cylinder and the rod. To resolve this, increase the air pressure to the appropriate level and check the alignment of the cylinder and rod to ensure they are properly positioned.

Another frequent problem is weak force output, often resulting from either insufficient air pressure or an internal seal leak. Start by verifying that the system is operating at the correct pressure. If the force remains weak despite proper pressure, it likely indicates that the internal piston seal is worn and needs to be replaced.

Air leakage is also a common fault, usually caused by worn seals or loose fittings. Begin by inspecting and tightening all air connections. If the leak is coming from the rod or exhaust port, the issue is more serious—internal seals have likely deteriorated and must be replaced.

In summary, issues like crawling, weak force, and air leakage generally stem from low air pressure, misalignment, or damaged seals. Regular checks on air pressure, installation alignment, and seal integrity, along with timely maintenance or replacement, are essential for keeping pneumatic cylinders running smoothly.

A: Connecting them is straightforward. Here’s a simple guide: First, identify the ports—locate the air port(s) on your cylinder and the outlet port(s) on your solenoid valve. For a single-acting cylinder, which has one port, connect it to an outlet port on the valve. For a double-acting cylinder, which has two ports, port ‘A’ is typically for retraction, and port ‘B’ is for extension, so match these to the corresponding ‘A’ and ‘B’ outlet ports on the valve. Next, select the right fittings, such as push-to-connect fittings, that match the thread size of the cylinder/valve ports and the diameter of your air tube. Then, connect the tube by firmly pushing one end of the air tube into the valve’s outlet fitting and the other end into the cylinder’s fitting, ensuring a secure, leak-free connection. Finally, as a tip, always use an air source with a filter-regulator-lubricator (FRL) unit installed before the solenoid valve to ensure clean, properly pressurized air, which protects your components and extends their lifespan.

*We respect your confidentiality and all information are protected.

*We respect your confidentiality and all information are protected.

*We respect your confidentiality and all information are protected.

Copyright © 2023, Omch All rights Reserved.

*We respect your confidentiality and all information are protected.