Introduction: The Unstoppable Shift to Manufacturing Automation

In the contemporary manufacturing industry, change is a necessity to succeed. With changing market demands, the growing complexity of the entire supply chain requiring sophisticated supply chain management, and rapid technological changes, the manufacturing sector is heading in one direction: automation technology. This subject is no longer restricted to multinational companies or highly sophisticated manufacturing plants. Manufacturing automationhas become a key element of competitiveness, a paradigm shift in the way the manufacturing process is done that not only defines industry leaders, but industry survivors. To any manufacturer who wants to improve efficiency, ensure quality, and have a sustainable future, the question is no longer whether they should automate but how and when.

This paper will be your guide to this critical topic. We shall start by defining the fundamental concepts of manufacturing automation, and this will provide a firm and concrete basis of knowledge. We will then examine the transformative value it offers and look at the major applications where it is having the greatest impact across industries. Lastly, we will look at the technologies that make it all possible, with a special emphasis on the powerful, reliable, and highly effective role of pneumatic products, the essential components that provide the force and motion of so many automated systems. We aim to provide you with the information to not only comprehend this change but to be able to apply it to your own practices with confidence.

What is Manufacturing Automation? A Clear and Simple Guide

Manufacturing automation, often called industrial automation, is, at its most fundamental, the application of control systems—which may be as simple as a mechanical device or as complex as smart machines enhanced with artificial intelligence—to run the machinery and production processes of a factory with minimal human interaction. The main aim is to carry out tasks that are repetitive, physically demanding, or tedious tasks. This includes dangerous tasks or complex tasks that require a degree of precision humans find hard to sustain. It is about establishing manufacturing systems where work is determined by the process, mitigating the inconsistency and constraints of manual labor.

Although the term automation may imply a fully human-free factory floor, the reality is more nuanced. Automation can be applied at various levels, and it is important to understand the different types of automation to determine the most appropriate opportunities in your manufacturing facility. These levels are broadly divided into three main types of automation:

- Hard Automation (Fixed Automation): This is the simplest and least adaptable type of automation, sometimes relying on mechanical elements in the form of cams. It entails using production equipment specifically made to do one thing very well and in large quantities, achieving very high production rates. A mechanical bottling and capping line in a beverage plant or transfer lines to machine engine blocks are classic examples. The initial investment is usually high, but for mass production of a single product, the cost per unit is extremely low. The tradeoff is its rigidity; altering the product style necessitates a major, and often total, re-tooling of the equipment.

- Programmable Automation: This form of automation is used to process batch quantities of different products. The sequence of operations can be altered by changing the control program, often managed by programmable logic controllers (PLCs). The equipment is more general-purpose than in fixed automation. A good example of programmable automation is an industrial robot on a welding line that can be reprogrammed to weld different car door models, or a CNC machine that can cut various parts from a metal block based on the software it’s given. This type of automation is best for batch production where volumes are medium to high but product designs vary. There is non-productive production time during the changeover to a new product style, but it provides an important level of flexibility that hard automation cannot.

- Flexible Automation (or Soft Automation): As an extension of programmable automation, this is the most advanced and adaptable system. It enables the manufacture of a broad variety of products with practically no time wasted in changeovers. The system can adapt in real time to manufacture new products, often identified through barcodes or vision systems which aid in data collection. A classic example of flexible automation is a flexible manufacturing system (FMS) with several robotic cells, autonomous material handlers, and a central control computer. This is most appropriate in high-mix, low-volume production where product life cycles are short and demand is unpredictable. It is a major investment but provides the most operational flexibility.

The knowledge of these levels enables you to view industrial automation as a continuum of strategic choices rather than an all-or-nothing process.

The Core Benefits: Why Automation is a Game-Changer for Manufacturers

Manufacturing automation is not just a technical upgrade; it’s a strategic business decision that brings significant, quantifiable returns. These benefits of manufacturing automation touch all areas of an operation, from financial performance and lower operating costs to the safety record on the plant floor. Although the list of the benefits of automation is long, they can be grouped into three core areas.

Skyrocketing Productivity and Throughput

This is usually the most urgent and convincing motivation to automate. Automated systems don’t need breaks, aren’t subject to fatigue, and can work 24/7/365. This significant rise in uptime directly increases production output. An automated cell on a production line can do a job in seconds that a human might take a minute, and it will maintain that same speed consistently. This allows for predictable and higherproduction rates, which removes bottlenecks, streamlines theentire production process, and enables a facility to manufacture more products in the same timeframe at a lower cost. This increased throughput helps companies meet production goals, satisfy customer demand, decrease lead times, and generate more revenue without a corresponding increase in labor costs, especially on high-volume assembly lines.

Achieving Flawless Quality and Consistency

The risk of human error is an inevitable factor in any manual process. Fatigue, distraction, or misjudgment can cause inconsistencies that lead to product defects, rework, and scrap. Automation solutions are an excellent way to eliminate this variable. A robotic welder applies the same weld with the same parameters every time. A pneumatic gripperexerts the same force on every part it handles. This repeatability is the foundation of high product quality and effective quality control. Automating processes helps ensure that every product meets specifications, supporting robustquality management systems. This leads to a drastic reduction in scrap rates and warranty costs and, most importantly, a stronger brand image founded on uncompromising quality and reliability.

Creating a Safer and More Ergonomic Workplace

The shop floorcan be full of hazards, from heavy lifting and repetitive strain injuries to exposure to hazardous materials. Improvingworker safety is a key benefit of automation. It allows you to remove human labor from these dull, dirty, and dangerous tasks. Robots can be deployed to carry heavy loads, operate in harsh environments, or handle hazardous materials like in some chemical manufacturing processes. Monotonous movements that cause long-term ergonomic injuries can be replaced by simple automated systems. This not only minimizes workplace accidents and compensation claims but also frees your human talent for more valuable, cognitive work like quality oversight, machine programming, process improvement, and maintenance. It transforms the work environment from physical labor to technical supervision.

Where Automation Shines: Common Applications Across Industries

The real strength of automation is when you experience it. It is not a one-sided solution but a flexible toolbox that can be used in a variety of processes in almost any manufacturing industry. Being familiar with these typical applications can assist you in determining the greatest opportunities in your own facility.

| Area | Description |

| Material Handling and Conveyance | This involves the flow of raw materials, work-in-progress, and finished goods on the plant floor. Automation in this area can include conveyors, Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), and robotic arms for pick-and-place tasks. Integration with ERP systems helps streamline inventory management. |

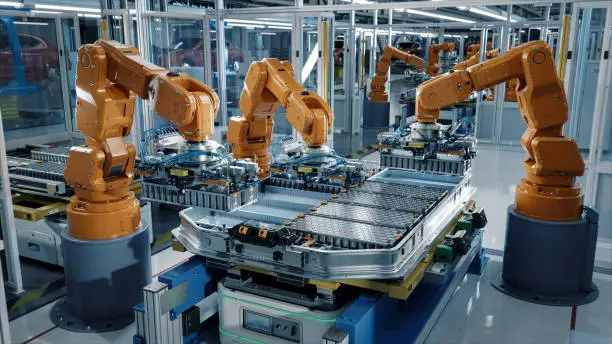

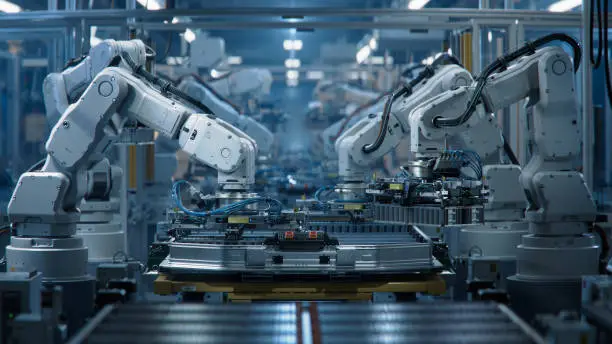

| Assembly, Welding, and Dispensing | Automation in product assembly involves repetitive tasks such as inserting screws, applying adhesives, and welding components. Robotic arms are used in the electronics industry to place microscopic parts onto circuit boards. In the automotive industry, robots weld car bodies. Automated dispensing systems apply precise amounts of materials like glue, sealant, or paint. |

| Inspection and Quality Control | Manual inspection is time-consuming and prone to human error. Automated inspection systems, using machine vision, lasers, and sensors, can check products for defects at high speed and with high accuracy. These systems ensure that defective products are removed early from the production line, and only perfect products reach the customer. Data from inspections can be used for process improvement. |

Automation of different phases of production can help companies to become much more efficient, minimize human error, and increase the quality of their products. Automation does not only simplify the processes but also enhances competitiveness of a company and gives it a good basis to grow in the long run.

The Key Technologies That Drive Modern Automation

To make those applications a reality, a number of fundamental technologies must work together. Although an automated system may appear to be complicated, it is usually composed of a number of functional elements. Knowing these building blocks is the initial step in creating a good solution:

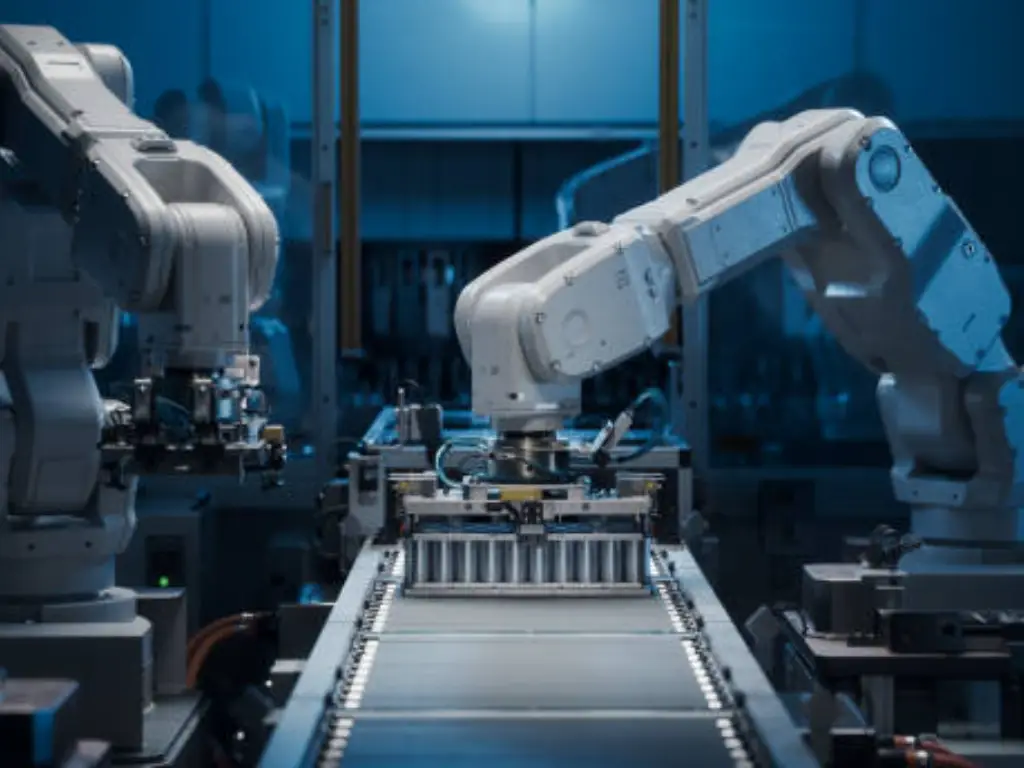

- Robotics: The most well-known part of automation is industrial robots, such as articulated arms and collaborative robots (cobots). They offer physical dexterity to perform such tasks as welding, painting, assembly, and material handling with strength, speed, and precision.

- Control Systems (Logic Controllers): The Programmable Logic Controller (PLC) is the industrial computer that is the brain of most automated systems. It takes input from sensors and executes a user-written program to control output devices like motors, valves, and actuators, coordinating the entire workflow.

- Sensors and Vision Systems: These are the sensory input to the automated system. Sensors are instruments that detect the presence, position, or properties of an object (e.g. proximity sensors, pressure sensors). Machine vision systems are cameras and software that process visual information, enabling them to direct robots, inspect parts to detect defects, and read barcodes or text.

- Human-Machine Interface (HMI): The HMI is the operator-friendly screen (usually a touchscreen) that enables a human operator to observe and control the automated process. It gives real-time data, alarms, and controls to start, stop, or adjust the system.

- Pneumatics: This is the study of the use of compressed air to create force and movement. Pneumatic systems, consisting of such elements as cylinders, valves, and actuators, are straightforward, high-powered elements that deliver physical force and motion to a myriad of automated processes. They perform the essential functions of gripping, clamping, pressing, pushing, and lifting in systems in all industries.

Although robotics and advanced software are often mentioned, the pneumatic system is the power and movement behind a great number of automated processes.

The Unseen Powerhouse: The Critical Role of Pneumatic Products

Pneumatic technology is a vital component of manufacturing automation, as it uses compressed air to generate fast, reliable and cost-effective motion. Although other technologies have come up, pneumatic products are still a vital part due to a number of reasons. By combining pneumatics with other industrial automation products, companies achieve scalable, flexible, and cost-efficient automation strategies.

- The first is that they are extremely cost-effective. The cost of initial investment in pneumatic components is much less than that of electromechanical or hydraulic components. A basic pneumatic cylinder and valve can generate linear motion and force at a small fraction of the cost of a servo motor and ball screw assembly. Moreover, compressed air systems are already a common utility in most manufacturing facilities, so integration is easy. This low initial investment enables even small and medium-sized companies to start their automation process with simple and high ROI projects.

- Second, they are extremely simple and dependable. Pneumatic systems are mechanically simple, having fewer moving parts than more complex electromechanical systems. This natural simplicity also makes them extremely rugged and durable, able to endure the rigors of a factory floor, such as vibration, dust, and temperature changes, with millions of cycles with little maintenance. Maintenance is usually quick and simple and can be done by in-house technicians without specialized programming knowledge. This equates to increased uptime and reduced total cost of ownership.

- Lastly, pneumatic systems are safe in most applications. They are also intrinsically safe to use in explosive or flammable areas where electric motors are a serious hazard. They may also be made overload-safe; in the event of an obstruction, a pneumatic cylinder will simply stall, whereas an electric motor can burn out. This qualifies them as a reliable option in applications that demand power and safety. In applications like automated material handling, pneumatic solutions provide smooth, safe, and efficient operations.

Choosing the Right Partner: Elevate Your Automation with Our Pneumatic Solutions

- Maximize Uptime: Reliable Quality, Delivered Fast

- Simplify Sourcing: 3,000+ Models from One Partner

- Built to Last: Lower Your Maintenance & Replacement Costs

- Tailored Solutions to Win Your Market

At Hebai-Omch, we recognize the pivotal role pneumatic technology plays in modern industrial automation. With 37 years of experience in providing high-quality industrial automation parts, we understand the challenges that businesses face, including the need for reliable, efficient, and cost-effective solutions. As industries increasingly rely on automation to enhance production speed and precision, choosing a trusted partner is essential. Our extensive product range is designed to optimize your production lines by delivering the highest quality and reliability. We ensure that your systems integrate seamlessly, providing you with consistent performance and minimal downtime.

Hebai-Omch stands out in the market by offering products that combine affordability with exceptional performance. We understand the pressures of high initial investments and the complexity of system maintenance. That’s why our pneumatic solutions are engineered for ease of integration, reducing maintenance efforts and costs. Our focus on high efficiency and long-lasting durability ensures that our components not only meet but exceed the demands of the most challenging industrial environments. From valves to fittings, tubing, and cylinders, each product is built to minimize disruptions and keep your operations running smoothly.

Choosing Hebai-Omch means more than just purchasing high-quality components; it’s about partnering with a team dedicated to your success. We provide comprehensive support through expert consultations, tailored solutions, and reliable after-sales service. Our 24/7 support and commitment to continuous innovation ensure that we are always there to meet your evolving needs. With our efficient logistics system, including same-day shipping from multiple warehouses across China, we guarantee that your operations stay on track, no matter the deadline. Trust Hebai-Omch as your partner in industrial automation and experience the difference in quality, reliability, and performance.

Success Stories: See Our Pneumatic Products in Action

The theoretical advantages of high-quality pneumatics are realized when you witness them overcoming real-life problems on the factory floor. These are only a few examples of how our products are a critical component in successful automation projects:

Automotive Assembly Lines

- The automotive manufacturing industry is a high-stakes game where every second matters. A large Tier 1 supplier was experiencing problems with their current pneumatic grippers that were not providing consistent clamping force, resulting in misaligned parts and line stoppages. They changed to our precision pneumatic clamp series.

- The Outcome: Our clamps solved the alignment problem with their strong design and uniform force delivery, which cut defects by 90% and boosted the overall equipment effectiveness (OEE) of the line by 12%.

Food & Beverage Packaging

- A large-scale bottling facility required automated material handling to improve the process of sorting and diverting bottles onto various conveyor lines. Since the environment was wet and needed frequent washdowns, reliability and hygiene were critical. We offered a solution with our food-grade, corrosion-resistant pneumatic cylinders and valves, which seamlessly integrated into the automated handling system to ensure efficiency and durability.

- The Outcome: The system is running perfectly at more than 100 cycles per minute and is holding up to the washdown environment without any problems. This has increased their sorting capacity by twofold and greatly decreased the cost of manual labor.

Electronics Manufacturing

- A manufacturer of sensitive circuit boards required a method of handling components with a firm but gentle touch. We supplied precision pressure regulators that were matched with compact pneumatic grippers to form an end-of-arm tool on their assembly robots.

- The Outcome: The system offers accurate, adjustable force control, enabling the robot to manipulate a broad range of delicate parts without damaging them, and cutting scrap due to handling errors by more than 30 percent.

Conclusion: Start Your Automation Journey with Confidence

The future direction for manufacturing is clear. Automation is not a luxury, but a strategic plan for building a more productive, efficient, and resilient operation. We have seen that it delivers transformative benefits in quality, throughput, and safety, with applications spanning every corner of the factory. And within this powerful world of automation, pneumatic technology continues to prove its worth as a simple, reliable, and cost-effective solution for generating the force and motion that gets the work done.

Making the decision to automate is the first step. The second, equally crucial step, is choosing the right technologies and the right partners to ensure that your investment yields the maximum possible return. A well-designed system built with high-quality, reliable components is a system destined for success. As an Automation Parts Distributor, partnering with Hebai-Omch means you’ll have access to top-tier products and support that will drive your business to new levels of efficiency and profitability.

Are you ready to power your automation with solutions you can trust?

Contact our team of pneumatic and automation experts today for a free consultation. Let’s build your factory of the future, together.