Accuracy is not an objective in the industrial automation world, but the foundation of reliability and performance. Each component has to perform its duty with uncompromising precision, cycle after cycle. Although the standard pneumatic cylinder is one of the workhorses of linear motion, there are widespread applications where the simple, direct force is not sufficient. When the job is more than just pulling or pressing, when it needs unwavering stability against off-axis loads—engineers reach for a more advanced solution: the guided pneumatic cylinder.

This guide is intended to be used by the engineer, the machine builder, and the technical buyer who realizes that the proper selection of components is the difference between a working machine and a really outstanding machine. We will dissect the guidedcylinder, starting with its basic application and working down to the nitty-gritty of selection and use, so that you will know how to specify the ideal solution, from a mini size to a large bore, for your most challenging automation problems.

What Is a Guided Pneumatic Cylinder and Why Do You Need One?

In essence, a guided pneumatic cylinder is a smart combination of two parts: a conventional pneumatic actuator and a built-in linear guide system. It is the direct solution to a very important question that many engineers have to ask themselves: “Why is my standard cylinder failing prematurely, or why can it not hold the position I require?”

Suppose we make a distinction:

- Standard Pneumatic Cylinder: It is used to supply linear force. The piston rod is made to be able to deal with axial loads (push/pull). It is not intended to withstand large side loads (forces perpendicular to the rod) or moments (torque). Exposing it to these forces results in premature wear of seals and bearings, threatening piston integrity and resulting in leaks, uneven performance, and eventual failure.

- Guided Pneumatic Cylinder: This is a special device designed to accommodate the axial thrust as well as disruptive transverse loads. It combines strong guide rods and high-performance bearing elements into one, compact, moving-as-one unit.

The choice of investing in a guided cylinder boils down to the acceptance of its fundamental benefits:

- High Precisionand Repeatability: It eliminates the possibility of the piston rod experiencing rotation, so that the tooling or workpiece at the head end is placed with high repetition accuracy, each and every time.

- Better Rigidity and Load Resistance: It is able to resist large side loads and moments that would cripple a conventional cylinder and offers particularly high stability under complex loading conditions.

- Space-Saving Integrated Design: It integrates the actuator and guide rail into a single unit, sometimes in a piggyback style, so there is no need to have a complex, bulky, and frequently expensive external guide mechanism like a separate linear gantry. This makes machine design and assembly easy.

- Simplified Engineering: When you select a pre-engineered guided unit, you eliminate the guesswork and complicated calculations involved in designing your own external guidance systems, offering potential savings in engineering time.

Essentially, you require a guided pneumatic cylinder when your application requires force to be applied with unwavering operational stability.

How a Guided Pneumatic Cylinder Works: The Dual-Action System

In order to understand its potential, we need to examine how it is built. The beauty of the guided cylinder is that it has two separate but collaborative systems that operate in perfect unison: one component gives the power and the other component gives the control for preciselinear movements.

The Driving Force: The Pneumatic Actuator Core

The core of the device is a pneumatic actuator which works on the same principles as any regular cylinder. It is a tested and trusted part of many air systems, producing linear motion using compressed air.

In a standard two-action model, the compressed air is introduced into a port on one side of the cylinder barrel. This force is applied to the surface of an internal piston, which is forced and the piston rods attached to it in a linear, smooth movement. The airflow is redirected through a control valve to a port on the other end, forcing the piston back to its initial position to retract. The force produced is proportional to the air pressure and the area of the piston (Force = Pressure × Area). This is the raw, linear force that does the work.

The Stabilizing Force: The Integrated Guide Mechanism

This is the source of the advanced capabilities of the device. While the pneumatic core gives the push and pull, the built-in guide mechanism is the unswerving protector of that movement. This system makes the cylinder have its name and its high performance.

- Preventing Rotation: The piston rod is not floating. It is firmly attached to a tool plate or yoke plate, which is, in turn, attached to two or more parallel guide rods. These guide rods move through precision bearings in the slide housing. Because the guide rods are fixed in their orientation, the whole assembly cannot rotate about its central axis. This is essential in applications such as screwdriving, part orientation, or any application where the end-effector needs to hold a certain angle.

- Resisting Side Loads and Moments: This is probably its most important role. When a side load or a bending moment is exerted at the end of the piston rod by an external force—whether due to the action of gravity on an overhung load, a vertical attachment, or a transverse push by another process—the effect is to cause the piston rod to bend. This force in a normal cylinder would push the piston rod directly against its bushing and seals, creating friction, wear, and eventual failure. These destructive forces are intercepted in a guided cylinder. The force is passed from the tool plate to the strong guide rods. These rods, being of greater diameter and wider spaced, then convey the load into the precision bearings (either slide or ball bearings). This system is very successful in isolating the pneumatic sealing elements against abusive side loads, ensuring minimum vibration transmission and dramatically increasing service life, reliability, and long-term precision.

The guided pneumatic cylinder is a sophisticated combination of power and steadiness. It can be used in harsh industrial environments because it is reliable, precise, and durable due to the combination of a strong actuator and a precise guiding mechanism. This synergy renders it a perfect solution in any place where strength and precision are not negotiable.

Key Types of Guided Pneumatic Cylinders: Which Is Right for You?

Having a clear understanding of the how, we may now consider the what. Guided pneumatic cylinders are not universal. They are available in a number of variants and configurations, each suited to different performance envelopes. The main differences are the guidance mechanism and the general structural form.

Guidance Mechanism Classification:

Slide Bearing (Bushing Guide): This is the heavy-duty workhorse of guided cylinders. The guide rods slide through long-life, self-lubricating bronze or polymer bushings.

- Strengths: Great in high-load, moderate-speed applications. They are also naturally more shock load resistant and excel in particulate contaminated environments (such as welding or woodworking shops) since the bushings naturally wipe. They are also cheaper.

- Best Use: Material handling, clamping, lifting, and heavy stopping.

Ball Bearing (Linear Ball Bushing Guide): This is the precision expert. It uses ball bearing elements, in which several rows of recirculating ball bearings are used on hardened and ground guide rods.

- Strengths: Provides much less friction, which means smoother, faster, and more accurate movement, leading to optimum cycle times. They are the preferred option when high-speed cycling and the highest repetition accuracy are required.

- Best Applications: High-speed pick-and-place, precision assembly, and test and measurement equipment.

Structural Form Classification:

| Type | Description | Key Features / Best Use |

| Compact Guide | Features a compact, low-profile design that minimizes the total height of the unit. | Ideal for applications with limited vertical space where guidance is still required. |

| Double Piston (Twin Guide) | Includes two guide rods, typically positioned on either side of the main piston rod, offering enhanced stability and rotation prevention. | Provides good anti-rotation and compact stability—a balanced design for general-purpose precision. |

| Heavy-Duty Guide | Built with oversized guide rods, a thicker tool plate, and a reinforced body to handle high loads and moments. | Best for long tools, heavy off-center loads, or high side-load applications. |

In the end, the “right” guided pneumatic cylinder isn’t just about specs—it’s about performance where it matters most. Take the time to match the cylinder type to your task, and your system will reward you with smoother motion, better uptime, and longer service life.

The Engineer’s Checklist: How to Size and Select a Guided Cylinder

The choice of the appropriate guided cylinder is a methodical procedure. Hurrying this phase is a formula for either over-engineering (wasted expense) or under-engineering (impending collapse). Use this checklist to get a perfect fit for your application, and always seek specific recommendations if unsure.

Step 1: Analyze Your Load (Axial, Side Load, and Moment)

*Hebai-Omch provides detailed charts explaining the maximum allowable side load under various conditions.

This is the most important step. All great forces have to be quantified.

- Axial Load: The pure push/pull force needed to move the mass.

- Side Load: A force that is perpendicular to the piston rod.

- Moment: The twisting effect of a load that is not centered on the central axis of the cylinder. Three types should be considered: Pitch (up/down), Yaw (left/right), and Roll (rotational). Manufacturer catalogs, from suppliers like Hebai -Omch give detailed charts of the maximum allowable side load and moment of each cylinder model, frequently as a function of the stroke length. You should always make sure that your calculated loads are within these published limits comfortably.

Step 2: Calculate the Stroke Length and Speed Required

*This video shows us how to measure cylinder stroke length.

- Stroke Lengths: What is the distance that the load must move? It is important to remember that the capacity of a cylinder to deal with moments reduces with the increase in the stroke. Guided cylinders are available in a large range of sizes and strokes.

- Speed: How fast should the cycle be done? This will affect your decision of using a slide or a ball bearing guide. At very high speeds, make sure that the cylinder has suitable accessories like adjustable air cushions or shock absorbers to avoid damaging internal impacts at the end of the stroke.

Step 3: Determine the Required Bore Size for Thrust

*Hebai-Omch understands the importance of bore size and therefore provides detailed parameters.

When you have the axial load (mass to be moved and any process forces), you can compute the thrust needed. Apply the equation: Thrust = (π × (Bore Diameter/2)²) × Pressure. It is always advisable to include a safety margin (usually 25-50%) to allow friction and pressure drops in the system. Choose a cylinder whose bore is large enough to comfortably deliver this thrust at the operating pressure of your system.

Step 4: Take into Account Accuracy and Environmental Requirements

- Precision: What is your tolerance for positioning? Ball bearing guides will guide you to high-precision tasks.

- Environment: Is the cylinder going to be used in a cleanroom, a food processing facility (which needs stainless steel and special lubricants), a dusty factory floor. Select materials and sealing options (e.g., rod scrapers) to fit the environment to provide a long service life. Check available mounting options to ensure compatibility.

Conclusion

An adequately sized and correctly chosen guided cylinder is not merely a part, it is a pillar of reliability, accuracy and efficiency within your automation system. Taking time to work through every point in this checklist, including the analysis of forces and the assessment of the environment, you will set the foundation of long-term performance and safety. Do not allow guesswork to ruin your design. Spend the time in the beginning, talk to manufacturers when necessary, and make sure that all the details are in line with the requirements of your application.

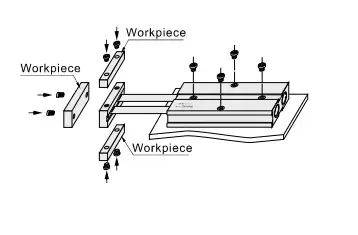

Common Applications: Where Guided Pneumatic Cylinders Shine

Theory is good, but a practical demonstration of a component makes it worthwhile. The widespread use of guided pneumatic cylinders shows they are the key elements of millions of automated processes:

| Application | Description | Key Advantage |

| Pick & Place Robotics | Used for vertical (Z-axis) movement in robotic arms. Elevates parts while maintaining perfect orientation, even with offset loads caused by grippers and parts. | Provides stable lift and resists moment forces from end-of-arm tooling. |

| Conveyor Belt Stopping | Acts as a non-rotating, robust stopping block for halting products like heavy boxes on a conveyor. Designed to withstand repeated impacts without deflection or wear. | Offers durability under impact and precise position hold. |

| Precision Assembly | Ensures exact alignment when inserting components (e.g., pressing a pin into a hole), preventing tilting or jamming that can damage parts. | Enables accurate linear motion with minimal misalignment. |

| Part Clamping & Orientation | Used to clamp parts during machining or inspection without shifting or twisting, maintaining the exact position and orientation of the part throughout the process. | Provides rigid holding and orientation stability during operations. |

In these instances, the guided cylinder is not merely moving something; it is controlling it with authority, ensuring precision alignment, resisting external forces, and maintaining consistent performance even under dynamic or unpredictable conditions. This level of control transforms basic linear motion into a reliable, repeatable, and finely tuned mechanical process.

Hebai-Omch: Your Partner for Precision-Engineered Guided Cylinders

- MODELS: TN

- BORE: 10、16、20、25、32、40

- STROKE: 10-200+

Guided dual-axis cylinder. High-precision aluminum alloy cylinder, no deformation and no air leakage surface hard oxidation treatment, high-strength alloy precision grinding and processing of wear-resistant chrome-plated piston rod, high-quality anti-collision pads, imported O-rings, wear-resistant ring, self-lubricating piston ring, the internal magnet only external magnetic switch, clear threads without burrs, thickened base impact resistance, to adapt to a variety of complex installation environments.

*The above showcases our high-quality guided cylinders

At Hebai-Omch, we specialize in the development and manufacturing of high-performance guided cylinders that deliver superior stability and precision in automated production environments. Designed for demanding applications such as CNC machinery and vision inspection systems, our guided cylinders offer exceptional thrust control, accurate positioning, and resistance to side loads. With 37 years of engineering experience, our products are trusted by industries worldwide and comply with CE and RoHS standards, ensuring both performance and safety. As one of our core product categories, guided cylinders stand out as excellent tools for achieving high-efficiency, high-accuracy motion control in automation systems.

To meet the unique needs of various industries, we provide flexible customization options for our guided cylinders. Customers can select from a broad selection range, including stroke lengths from 10 mm to 2000 mm and bore diameters ranging from Ø12 mm to Ø320 mm, with the possibility to customize even larger sizes for heavy-duty use. Material options include aluminum alloy, stainless steel, and carbon steel, ensuring maximum durability and corrosion resistance in any environment. Our guided cylinders are designed in accordance with ISO 6431, offering robust overload protection between 150%–200% of rated load and complying with ISO 13849 and ISO 61508 for enhanced safety and automatic shutdown functionality.

As a trusted manufacturer, we offer more than just components—we deliver complete solutions. Hebai-Omch supports your operations with same-day shipping from our multiple warehouses in China, 24/7 technical support, and optional secondary processing services such as CNC machining and surface finishing. Our guided cylinders feature lifespans of 3 to 10 million cycles and IP65/IP67/IP68-rated protection, making them ideal for harsh industrial environments. Backed by decades of manufacturing expertise and an extensive product portfolio that spans multiple cylinder categories, we ensure that your production line is equipped with the most excellent tools available in the market today.

Avoiding Common Pitfalls: Tips for Installation and Maintenance

Poor implementation can bring down the best component. These are the best practices to follow to ensure that your guided pneumatic cylinder has a long life and performance, moving beyond the status quo of frequent replacements.

Best Installation Practice:

- Mounting Surface: The surface on which the cylinder body is mounted must be absolutely flat and stiff. The cylinder body may be distorted by a warped mounting surface, and the guide rods may bind in their bearings.

- Load Alignment: As much as possible, align the center of gravity of your load with the central axis of the cylinder. The nearer the load is centred, the smaller the moment, and the greater the bearing life.

- Correct Tooling Connection: Utilize the given threaded holes on the tool plate. Welding should not be done directly to the plate because the heat may distort and destroy internal parts. Make sure that all fasteners are torqued to the specification of the manufacturer.

Maintenance and Troubleshooting:

- Periodic Inspection: Periodically inspect to see any indication of side-to-side play in the tool plate with the rod extended. Bearing wear is an early sign of excessive play.

- Cleanliness: Maintain the exposed guide rods clean. Some cylinders are fitted with rod scrapers, but wiping the rods down occasionally will ensure that abrasive grit is not sucked into the bearings.

- Lubrication: The majority of contemporary guided cylinders are life-lubricated. But in lubricated air systems, make sure that the lubricant is compatible with the seal materials of the cylinder (usually Buna-N or Viton).

- Jerky Motion: In the event the motion of the cylinder becomes jerky or hesitant, it may be caused by a lack of air pressure/flow, binding of the bearings (check alignment and for contamination), or wear of the internal seals.

Conclusion: The Smart Choice for Robust and Precise Automation

The guided pneumatic cylinder is more than an incremental improvement over its standard counterpart; it is a fundamental shift in capability. It is the component of choice when linear motion must be delivered with an unwavering hand, immune to the disruptive forces that exist in any real-world mechanical system. The advantages of linear motion are fully realized when control and stability are guaranteed.

By internalizing the principles of its operation, understanding the key types, and following a methodical selection process, you empower yourself to design machines that are not only faster and more precise but also vastly more reliable.

Choosing the right component is half the battle. The other half is choosing the right partner. For a truly neutral assessment of your needs and access to the best pneumatic drives, you need a partner with the engineering expertise to guide your selection and the manufacturing excellence to deliver a product that will not let you down. As you move forward with your next automation project, remember that the foundation of robust and precise motion is often a component built for that very purpose. That’s why engineers around the world trust Hebai-Omch — a partner that combines deep pneumatic expertise with precision manufacturing to deliver guided cylinders built for lasting performance.