Introduction: The Final, Critical Step in Your Production Line

The final stage of the modern manufacturing process is usually overlooked. Much attention is paid to the creation, fabrication, and assembly of products. Nevertheless, the activities that occur immediately prior to the shipment of a product have an out-sized influence on profitability and brand integrity. This is the role of line packaging. It has long been considered as a simple operational requirement or a cost center that should be reduced. This is a big miscalculation.

Your end of line (EOL) process is the final touch point with your product before it is delivered to the customer. It is the protective cover that takes it through logistics and the last phase of quality control, ensuringproduct integrity. A poorly packed case, an unstable pallet, or an inefficient process is not only a cost, but a risk. A risk of damaged goods, a risk of supply chain delays, and a risk of reduced customer experience.

On the other hand, well-developedpackaging solutions that are efficient, reliable, andautomated are a great competitive advantage. It turns a possible bottleneck into a smooth part of the value chain, so that the quality you designed into your product is maintained until it reaches its destination. This paper will explore the essence of that change. We will examine the essential automated operations that characterize contemporary EOL packaging and shed light on the potent, frequently invisible technology that makes them possible: industrial pneumatics. It is time to stop viewing packaging as an afterthought and start thinking of it as the strategic imperative it is.

What is End-of-Line Packaging? A Quick Overview

Before we tear apart the mechanics of efficiency, we need to have a clear picture of the field. What is end of line packaging? In the most basic terms, it involves all the activities that are undertaken to get a finished product ready to be warehoused and shipped once it has gone through its initial manufacturing and filling processes. It is the movement of individual items to shipment-ready units.

Think of it as a series of major steps, each of which is aimed at consolidating, protecting, and identifying goods to be transported. Although the details may differ widely between industries, such as food and beverage, pharmaceuticals, and consumer goods, the fundamental functions are very similar. This sequence normally comprises several levels of packaging:

- Case Forming & Packing: The individual products, often in their primary packaging like pouches or bottles, are packed together and placed into a secondary container, most often a corrugated cardboard case or one of many types of cartons. This starts with a machine constructing a flat box into its three dimensional form.

- Case Sealing: The case should be sealed after filling. This case sealing is normally done using industrial tape or adhesive glue to ensure that the contents are not contaminated and spillage does not occur.

- Labeling and Coding: Vital tracking and product data, including barcodes, batch numbers, and expiration dates, are printed and affixed to the case. This labeling is a non-negotiable step in contemporary inventory management, regulatory compliance, and traceability.

- Palletizing: The cases are then stacked in a predetermined and stable pattern onto a pallet. This palletizing is an important step that combines dozens of individual cases into one large unit that can be easily transported by a forklift or pallet jack.

- Stretch Wrapping & Securing: The fully loaded pallet is then wrapped in layers of stretch film. This stretch wrapping holds the cases together, creating a solid, cohesive unit that is not subject to shifting, moisture, and debris during transport.

When these phases merge into each other on the packaging line, the outcome is a secure, stable and traceable unit load, which is ready to be distributed. When they fail to, the repercussions are felt on the whole production schedule. The first step to optimizing this sequence is to understand it.

Key Processes in Modern End-of-Line Packaging Automation

The distinction between a slow, labor-intensive EOL process and a fast, efficient one is one word: automation. Human intervention adds variability, ergonomic hazards, and a definite throughput limit while increasing labor costs. Automated systems, in their turn, provide uncompromising consistency and speed. Let us take a look at the main automated processes that are the basic elements of modern EOL operations.

Case Erecting and Sealing: Building the Foundation

The first step to a successful packaging process is a perfectly made box. An automated case erector is one of the essential packaging machines for mechanical precision. It takes one flattened corrugated blank out of a magazine, squares it up to its rectangular shape, folds the bottom flaps and tapes or glues them. This is done in a few seconds, and a steady flow of ready-to-fill cases is produced much faster and with much more uniformity than any human operator could do.

The case is then filled and passed to a sealer. Its presence is sensed, it is positioned, and mechanisms are activated to fold the top flaps and apply a secure seal with precision. The uniformity of this seal is the most important; it is the most important step that guarantees the integrity of the product. A defective seal may cause contamination, damage, or theft. Automation eliminates the guesswork, exerting the right amount of pressure and adhesion each and every time.

Product Packing: Precision and Speed in Action

The process of getting the products into the waiting case is one that involves precise and coordinated movements. This is where case packers are used for case packing. Depending on the product characteristics, i.e., whether it is rigid bottles, flexible bags, or delicate cartons, various technologies are used. Drop packers drop products downwards, whereas side-load or bottom-load packers are used to handle products that need more careful orientation. This is a critical form of secondary packaging.

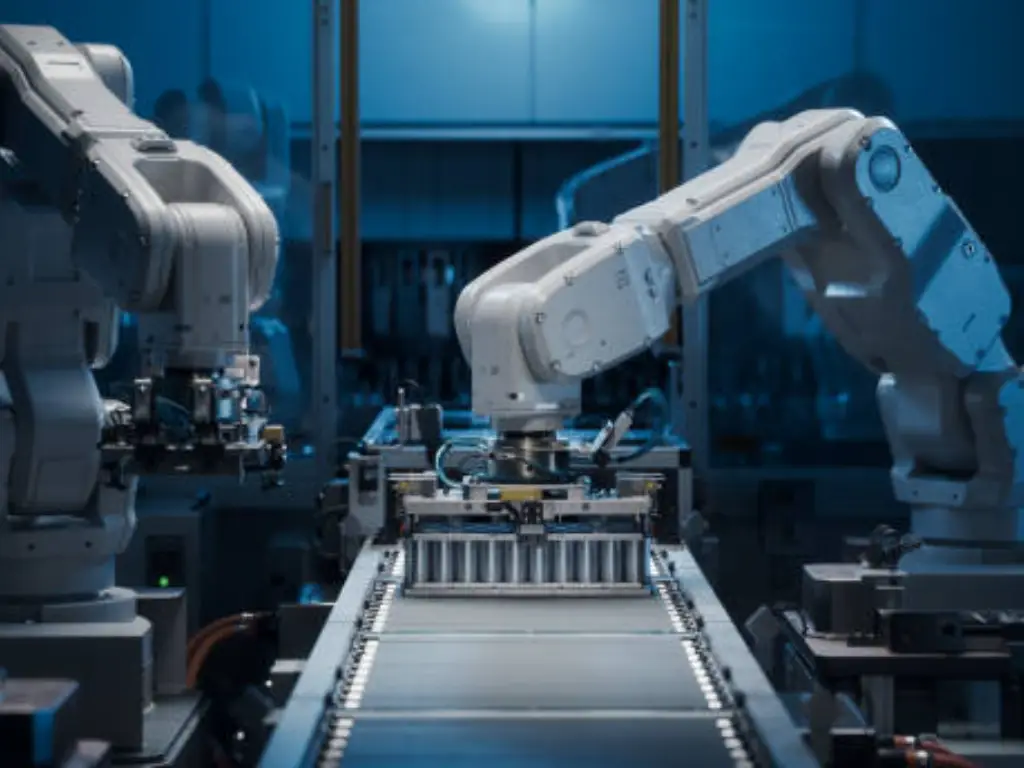

Roboticautomationis very efficient at this stage. A multi-axis robotic arm with a custom-designed end-of-arm tool (EOAT), or gripper, can pick and place products with a combination of speed and delicacy that is beyond human capabilities. It is able to orient items, place them in intricate patterns to maximize case density, and work with multiple product types with a simple software change. This is not merely a matter of substituting manual labor; it is a matter of attaining a degree of precision and throughputthat was previously unheard of.

Palletizing: The Heavy Lifting, Automated

*The video demonstrates the process of palletizing

The monotonous, physically strenuous nature of the job of placing heavy cases on a pallet is an excellent candidate to be automated, and a leading cause of workplace injuries when done manually. Automated palletizersare very productive machines in EOL operations and a key component of effective material handling.

There are two main forms of it. Traditional palletizers employ a set of conveyors and mechanical platforms to orient and stack cases in a pre-determined pattern. They are very quick and suited to high-volume lines that produce one product. Roboticpalletizers, however, provide a new level of flexibility. Similar to their case-packing counterparts, these high-powered robotic arms can be programmed to work with different case sizes, create complex interlocking patterns to provide more stability, and even work on multiple production lines at the same time. They do the laborious task of piling into a smooth, smart, and continuous process.

Stretch Wrapping: Ensuring Stability for Transit

The last step in the process of ensuring the load is the stretch wrapper. Unstable pallets pose a huge financial risk in transit. Automated stretchwrappers do away with this risk. A turntable machine rotates the pallet and a roll of film moves up and down a mast, providing consistent tension and overlap to bind the load into one solid unit. This wrapping is a reliable way to achieve product protection.

More sophisticated rotary arm wrappers hold the pallet still-suitable to light or unstable loads-and rotate the film around the pallet. The most important aspect of wrapping is the accurate control of film pre-stretch and tension. Automation also means that each pallet is given the precise amount of containment force necessary to hold its particular weight and configuration, maximizing film usage and ensuring that the load is stable without crushing the product inside. This is the last stage to make sure that your product is safe during transportation and shipping.

The “Unseen Engine”: Why Pneumatics are Essential for EOLP Automation

Behind the exact motions of this automated machinery—the folding of flaps, the gripping of products, the positioning of cases— there is a powerful and elegantly simple technology: industrial pneumatics. It is the fundamental source of energy that transforms compressed air into directed movement and force, which allows the functioning of the whole system of end of line packaging automation.

Why pneumatics? In the age of sophisticated electronics and robotics, why is this mature technology the preferred solution to so many packaging applications? The solution is in a combination of benefits that are ideally suited to the factory floor.

- Cost-Effectiveness and Simplicity: Pneumatic parts, such as cylinders, valves, actuators, are relatively cheap to manufacture and are very simple in their design. This translates to reduced initial cost of purchasing machinery and simpler maintenance of the equipment throughout its life. There are less complicated components to break and when they do, they can be easily replaced by plant maintenance personnel.

- Reliability and Durability: The factory floor is a harsh environment, subject to dust, vibrations, and temperature fluctuations. Pneumatic systems are robust in nature. They are able to work tirelessly through millions of cycles with little maintenance and can withstand conditions that would destroy more delicate electronic parts. Their reliability is a key to high Overall Equipment Effectiveness (OEE) and greater operational efficiency.

- Cleanliness and Safety: In food and beverage and pharmaceutical industries, hygiene is not an option. Pneumatic systems are a perfect choice because they work on clean, filtered air, and there is no risk of hydraulic fluid leaks that may contaminate products. They are also inherently safer in areas where explosive dust or fumes can be found, since they produce no sparks. A proper product inspection process is also easier to maintain.

- Power Density and Speed: Pneumatic actuators produce a lot of power relative to their size and weight. They are able to generate enormous linear force and perform movements with extreme velocity, which makes them ideal in case erecting, packing, and sealing, which involves rapid and repetitive motions. This power-to-size ratio enables smaller and more efficient machine design.

Compressed air is the invisible but vital energy source of EOL automation, whether it is the small cylinders that open a case flap or the vacuum grippers that lift a product, or the large actuators that push a full layer of cases onto a pallet.

Solving Your Bottlenecks: How Our Pneumatic Solutions Elevate Your EOLP

- Maximize Uptime: Reliable Quality, Delivered Fast

- Simplify Sourcing: 3,000+ Models from One Partner

- Built to Last: Lower Your Maintenance & Replacement Costs

- Tailored Solutions to Win Your Market

At Hebai-Omch, we understand the challenges businesses face in the end-of-line packaging (EOLP) process, where efficiency, cost control, and reliability are crucial. A single bottleneck in production can lead to increased downtime and reduced productivity, ultimately impacting profitability. That’s why we offer high-quality pneumatic components designed to optimize your operations. With over 37 years of expertise in industrial automation, we are committed to delivering solutions that ensure smooth, uninterrupted production and help you tackle your most pressing challenges.

Our pneumatic components are manufactured with advanced techniques and premium materials, offering unparalleled reliability. Our cylinders are built to withstand harsh environments and have an extended lifespan ranging from 3 million to 10 million cycles. Whether you’re using our cylinders, valves, or fittings, you can trust that they will perform consistently, reducing the likelihood of equipment failures and minimizing downtime. This reliability ensures your production lines continue to run without interruption, helping you maintain high efficiency and meet tight deadlines.

Hebai-Omch also excels in delivering solutions that enhance both speed and precision. Our high-performance pneumatic cylinders and valves are engineered to respond quickly and accurately, enabling faster production cycles without compromising quality. Whether in food, pharmaceuticals, electronics, or automotive manufacturing, our products allow you to increase throughput, reduce cycle times, and maintain precise control over the packaging process. Moreover, we offer customized solutions tailored to your specific needs, ensuring you get the best fit for your operations and optimal performance across every application.

The Future of End-of-Line Packaging: Trends and Innovations

The packaging world is not stagnant. It is continuously changing to address emerging needs of sustainability, data integration, and flexibility. The pneumatic technology that drives these systems is also changing along with it. Keeping up with these trends is the way to create a resilient and future-oriented operation.

One of the most prominent trends is the development of Smart Pneumatics. This includes the integration of sensors and connectivity into pneumatic devices such as valves and cylinders. These devices are able to track their own performance in real-time-cycle counts, pressure levels, and response times. This information is relayed to a central control system, where predictive maintenance is possible through analytics. Rather than waiting until a component fails and causes a shutdown, the system can notify maintenance teams that a seal is becoming worn or a pressure drop is indicative of a leak, so that it can be replaced during a scheduled downtime. This is the industrial Internet of Things (IIoT) at work, changing maintenance into a strategic process.

Moreover, the worldwide trend towards sustainability is transforming the design of every type of packaging. Companies are shifting to lighter weight materials, thinner films and recycled-content cardboard. These new materials may act differently in automated equipment. Pneumatic systemsare evolving to include more advanced pressure and flow controls, enabling machines to work with delicate, variable materials as precisely as traditional machines. The capability to adjust forces in real-time is critical to avoiding jams and achieving quality in next-generation packaging.

Making the Right Choice for Your Automation Journey

We began by stating that your end-of-line packaging process is a critical strategic imperative, not just a cost center. Optimizing it through automationis one of the highest-impact investments you can make to boost throughput, reduce operational costs, and protect your brand’s reputation for quality.

As we have seen, at the very core of this powerful automation lies the elegant, robust, and relentless power of pneumatics. From erecting the first case to wrappingthe final pallet, these durable components execute millions of cycles with precision and reliability. However, the success of your automation journey hinges on the quality of its foundational components. Choosing a partner for your pneumatic systems is a decision that will directly impact your uptime statistics and production reports for years to come. It requires a partner who not only provides exceptionally reliable and high-performance products but also brings deep application expertise to the table. It requires a partner committed to solving your problems, not just selling you parts.

To achieve maximum endurance and speed, your production linerequires high-quality, purpose-built components. Let us help you select them. Contact our automation specialists today for a complimentary assessment of your end of line packaging need.