The Modern Warehouse Challenge: The Urgent Need for Speed and Precision

The logistics world is in a continuous acceleration. In recent years, a combination of factors, including the inexorable rise of e-commerce, the narrowing of delivery windows required by customers, and rising labor costs, has transformed the landscape. The warehouse, which was once a fixed point in the supply chain, is now supposed to act as a high-velocity order fulfillment engine. This new reality poses a daunting challenge: how to process ever-increasing order volumes with greater speed, flawless accuracy, and sustainable economics. In an increasing number of operations, the answer is no longer a matter of debate. It is warehouse automation.

When we imagine the automated warehouse, we tend to think of the most visible aspects: fleets of autonomous mobile robots moving across floors and advanced software that coordinates all the movements. These are the most visible parts of the warehouse system. Yet, beneath this digital choreography lies a more fundamental layer of technology responsible for the physical work—the rapid, repetitive, and powerful actions that define modern logistics. This is the field of pneumatics. The tangible implementation of digital commands is made possible by the application of compressed air, a very simple and effective source of power. To get a clear picture of the automated warehouse, we have to go beyond control systems and see the technology that provides physical power and action.

What Exactly Is an Automated Warehouse System?

*The video explains the differences between AMR and AGV robotic solutions in warehouse automation, helping you make a choice.

It is necessary to define what it is before getting into the mechanics. An automated warehouse system is a complex of machinery, robotics, and software that is used to automate and streamline processes. It handles the most important warehouse operations, including receiving and storage, picking, and shipping. The aim is to reduce manual intervention, hence maximize efficiency, accuracy, and throughput. Although each system is customized to meet unique requirements, they are typically constructed from a set of core technological components, representing various types of warehouse automation.

It is necessary to define what it is before getting into the mechanics. An automated warehouse system is a complex of machinery, robotics, and software that is used to automate and streamline processes. It handles the most important warehouse operations, including receiving and storage, picking (in particular, automated warehouse picking), and shipping. The aim is to reduce manual intervention, hence maximize efficiency, accuracy, and throughput. Although each system is customized to meet unique requirements, they are typically constructed from a set of core technological components, representing various types of warehouse automation.

- Automated Storage and Retrieval Systems (AS/RS): These retrieval systems are the main technologies to achieve high-density storage. An AS/RS, often called an rs system, consists of a structure of high racking, computer-controlled cranes, and shuttles, and automatically manages storage locations to store and retrieve goods with unbelievable speed and accuracy. It is the solution to maximizing the available space and utilizing the vertical warehouse space in a facility, turning the ceiling of a warehouse into a resource amidst space constraints.

- Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs): This group includes the mobile transport vehicles of the warehouse. AGVs are usually programmed to move along fixed routes (magnetic strips or wires) to deliver goods, whereas AMRs use sensors and AI to move dynamically, selecting the most efficient routes. They are used to perform such tasks as moving pallets, delivering shelves to picking stations (“goods-to-person”), and delivering finished orders to shipping docks. These are just two of the various automation technologies available.

- Conveyor and Sortation Systems: These conveyor systems are the systems that ensure continuous movement and flow of goods. Conveyors move products along predetermined routes, whereas sortation systems, which may use high-speed diverters and pushers, move individual packages to their respective destinations, which may be a specific packing station or a shipping lane to a particular carrier.

- Warehouse Management System (WMS): This is the main control center of the whole operation. The warehouse management system (WMS) is a software system that controls and optimizes all the processes of the warehouse, from inventory management and order processing to labor management and system diagnostics. As a type of inventory management system, it is crucial for effective inventory control and maintaining optimal inventory levels. It gives the real time information and commands that direct the hardware to execute its functions.

All these elements form a unified, high-performance environment. However, to have machinery physically interact with products, it needs technology that is fast, reliable and powerful. This is where pneumatics comes in the picture.

Why Automation Is No Longer an Option, But a Necessity

The move to automation is not a fascination with technology as an end in itself, but a strategic reaction to crushing operational and economic demands. In the case of modern warehouses and a distribution center, automationhas become a basic necessity of survival and growth. The value proposition is evident, powerful, and quantifiable in a number of areas where manual processes fall short.

Slashing Operational Costs and Boosting ROI

Manual labor is always one of the biggest operational costs in a warehouse. Automation is a direct solution to this problem as it can take over repetitive work such as transportation, lifting, and sorting, and minimize the effects of labor shortages and wage increases. Although the initial capital outlay in an automated system represents a significant investment and high cost, the ROI is often achieved much sooner than expected. The savings are not limited to salaries; less human error means fewer costly returns, less insurance premiums due to a safer working environment and optimized use of machinery can even reduce energy consumption per unit handled. The financial math is simple: automation transforms a fluctuating, continually rising operational cost into a fixed capital cost with a definite and often short payback period.

Achieving Near-Perfect Accuracy to Enhance Customer Satisfaction

In the era of e-commerce, a wrongly picked or shipped orderis not just a logistical mistake, but a direct hit to customer trust and brand image, impacting customer satisfaction. The price of one error is compounded by the cost of shipping back, restocking, and shipping a replacement. Even in the most well-managed facilities, manual picking processes have an error rate. An automated system with the exact logic of a WMS and barcodes has an accuracy rate of 99.9 percent or more. This almost perfection is not only an operational measure, but a competitive edge. It makes sure that the right product reaches the right customer, at the right time, every time, which is the basis of loyalty that is the key to long termsuccess.

Maximizing Your Warehouse Footprint and Throughput

Real estateis costly and increasing a warehouse footprint is not always an option. Automation enables companies to achieve more with the storage space that they already possess. The effective use of space is critical. Automation technologies such as AS/RS can boost storage density by up to 85 percent over conventional racking because it uses vertical space well beyond the reach of a forklift. This enables a company to hold much more inventory in the same amount of square footage. Moreover, automation systems do not take breaks or shift changes. This huge boost in operational uptime translatesto a massive increase in the throughput of the facility, the amount of goods it can process in a given time, and thus a business can scale its operations without a corresponding increase in physical space.

The Unseen Powerhouse: Pneumatics’ Core Role in Driving Automation

In an era of advanced electronics and sophisticated software, it may be surprising to discover that a technology using compressed air is still a mainstay of industrial automation. However, a pneumatic system is not an old technology; it is necessary and in many cases a better solution to a huge number of applications in the automated warehouse. They are the origin of the system rapid-response actuation, the fast, powerful and reliable physical action that makes digital commands real.

The benefits of pneumatics lie in physics and practicality. Compressed air, typically supplied by an air compressor, is a clean, readily available, and cost-effective source of power. Leaks do not pollute the environment as in hydraulic systems, which is important in food, beverage, and medical applications across various industries. However, the main causes of its popularity are performance-related:

- Speed: Pneumatic actuators are capable of very high speeds and cycle rates, which are often not possible with purely electromechanical systems. This is what makes them suitable in high-throughput applications such as package sorting where actions have to be performed in milliseconds.

- Power Density: Pneumatic cylinders have an outstanding power-to-size ratio. They are able to produce enormous power per square inch out of a very small and lightweight package, which is a vital feature in applications such as robotic grippers and lifting mechanisms where weight and space are at a premium.

- Simplicity and Reliability: A pneumatic system is simple in mechanics. A cylinder, a valve, and some tubing are all that is usually required to generate linear motion. This simplicity is directly converted into high reliability and easy maintenance, requiring little maintenance over their lifespan. They are relatively resistant to electrical noise, vibrations, and temperature changes that can be problematic to more delicate electronic parts. They are made to withstand millions of cycles in harsh industrial applications.

- Cost-Effectiveness: Pneumatics can be the most cost-effective method of generating fast, repetitive linear motion, both in terms of initial component cost and long-term operating cost.

In a nutshell, the WMS gives the what and where, whereas pneumaticsgives the decisive and powerful how. It is the essential technology that grabs, pushes, lifts, sorts, and places goods with a speed and reliability that is central to the entire automated ecosystem.

Pneumatics in Action: Key Applications Within the Warehouse

The best way to understand the power of pneumatics is to see it in action on the warehouse floor. It is in the performance of certain, essential functions in material handling that its worth becomes unquestionably evident.

| Application | Description | Key Technology |

| Sorting and Diverting | Primary conveyor belts move hundreds of packages every minute. Pneumatic pusher arms extend with high speed to divert packages to secondary conveyors. Perfectly regular and fast action. | Pneumatic Actuators (High Force & Fast Cycle Rate) |

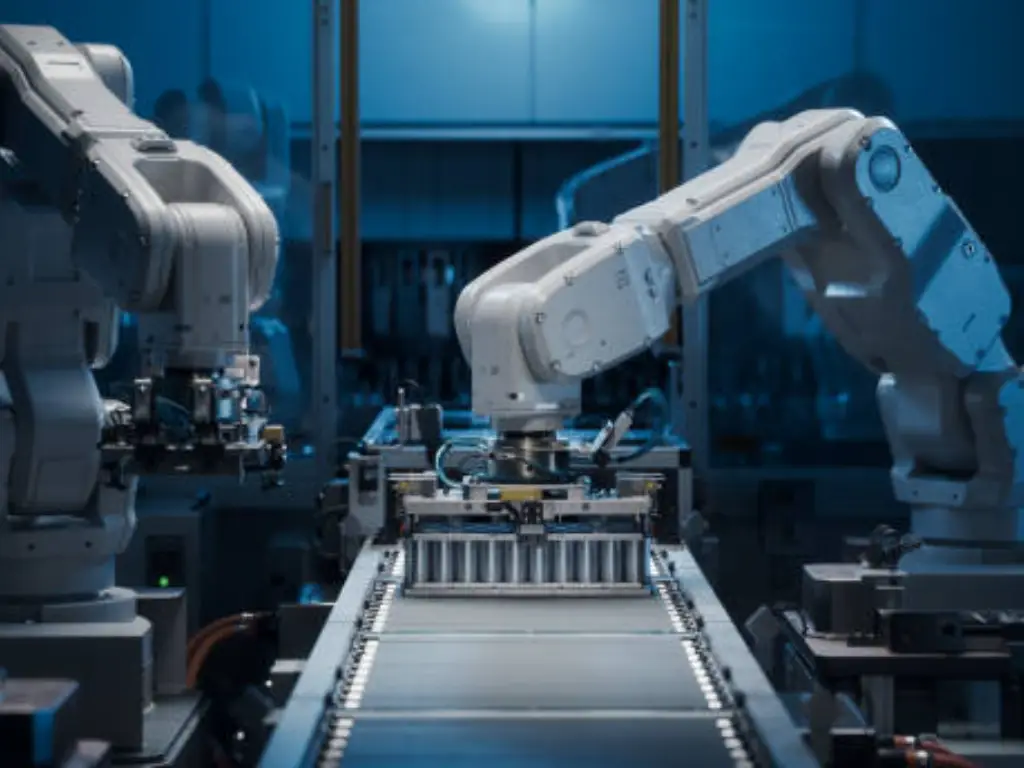

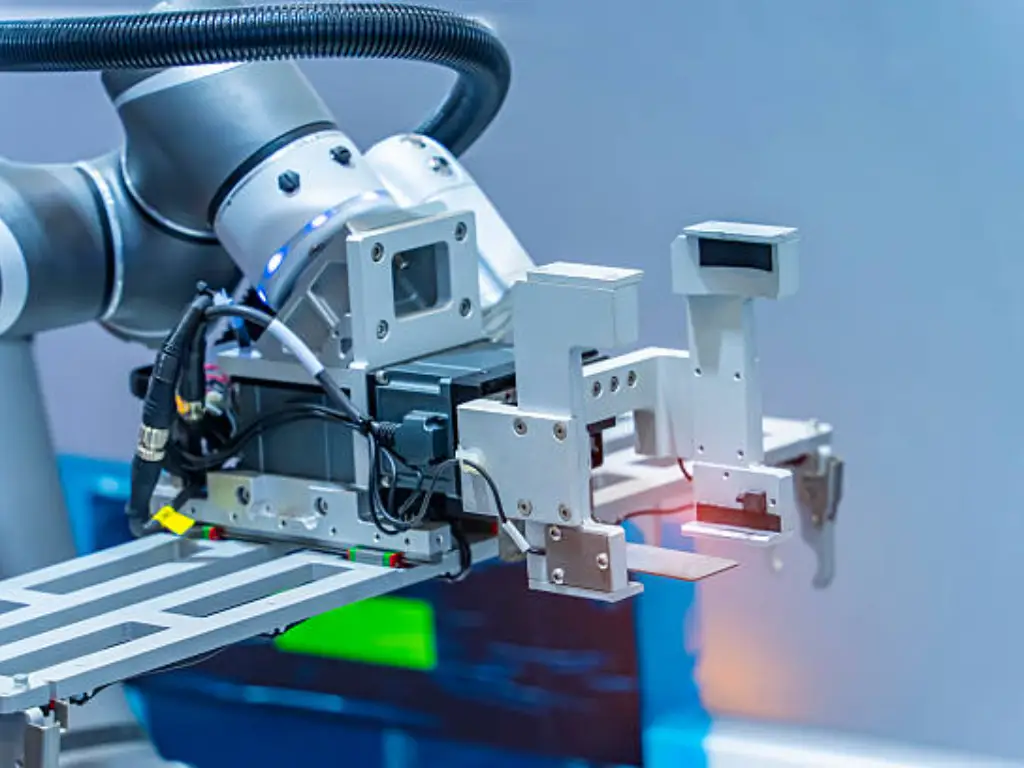

| Robotic End-of-Arm Tooling (EOAT) | Pneumatic devices power robotic arms, particularly the grippers (End-of-Arm Tooling). Grippers can handle delicate items or heavy boxes, and can also produce rotary motion for complex tasks. | Pneumatic Grippers (Versatile & Lightweight) |

| Lifting and Positioning | Pneumatic lift tables elevate heavy pallets, and small pneumatic cylinders halt or position products. These are essential for smooth and efficient warehouse operations. | Pneumatic Lift Tables & Cylinders |

These applications show the versatility and efficiency of pneumatic systems in warehouse applications. Whether it is sorting and diverting or robotic manipulation and precise positioning, pneumatics is a key technology in ensuring smooth, fast, and reliable performance, and it is therefore an essential technology in modern warehouses.

Choosing the Right Pneumatic Partner: Turning Components into Competitive Advantage

- Maximize Uptime: Reliable Quality, Delivered Fast

- Simplify Sourcing: 3,000+ Models from One Partner

- Built to Last: Lower Your Maintenance & Replacement Costs

- Tailored Solutions to Win Your Market

At Hebai-Omch, we don’t just provide parts; we offer solutions that help you achieve more and drive greater profitability. With 37 years of experience in industrial automation, we understand that selecting the right pneumatic partner is crucial to maximizing your business’s potential. Our high-quality components are designed to keep your production lines running smoothly, reduce downtime, and optimize your supply chain. By partnering with us, you’re not only securing reliable products but also gaining a competitive advantage that will help you grow your business and stay ahead in the industry.

Beyond Durability: How High-Performance Components Prevent Costly Downtime

At Hebai-Omch, we know that downtime can be one of the most expensive problems your business faces. That’s why we focus on delivering pneumatic components that offer unmatched durability and performance. Hebai-Omch’s pneumatic components are designed with longevity and reliability in mind, minimizing failure and downtime risks. Our products, such as pneumatic cylinders, pneumatic valves, FRL units and fitting & tubing & accessories are certified to ISO 9001 standards and undergo strict testing, ensuring exceptional performance, longer service life, and fewer maintenance needs. With fewer breakdowns and lower maintenance requirements, our components keep your operations running smoothly, ensuring that your production line operates at full capacity, reducing costly disruptions and maximizing your profitability.

Custom Solutions for Your Unique Automation Challenges

No two businesses are alike, and neither are their automation needs. At Hebai-Omch, we specialize in providing custom pneumatic solutions tailored to the specific requirements of your production processes. Whether you need specialized components for unique load, speed, or environmental conditions, we have the expertise to deliver optimal solutions. By choosing Hebai-Omch, you are not just getting a supplier; you are gaining a technical partner who works with you to ensure your automation systems are designed for peak performance. Our commitment to innovation and continuous improvement ensures that our solutions are always on the cutting edge, helping you optimize efficiency and increase profits.

The Future is Smart: Evolving Pneumatics in the Era of IIoT

The development of pneumatics has not ceased. The next step is to integrate intelligence into the components themselves using advanced technologies. As adoption grows, the role of reliable industrial automation parts suppliers becomes central to advancing smart pneumatics. This is the age of smart pneumatics and the Industrial Internet of Things (IIoT). By integrating sensors into pneumatic valves and actuators, these software applications are now able to produce and transmit useful data regarding their own performance and condition.

Consider a pneumatic gripper that can tell you exactly how much pressure it is exerting, so that sensitive products are never damaged. Think of a pneumatic cylinder that keeps track of its own cycle count and seal integrity and sends an alert that it needs maintenance well before it fails. This is the strength of predictive maintenance. When this information is fed into a central WMS or analytics system using advanced algorithms and machine learning, operators can have an unprecedented view of the health of their machinery. They can transition out of a reactive, fix-it-when-it-breaks approach to a proactive, data-driven approach that maximizes uptime and optimizes performance. As an innovative partner, we are leading this transformation, creating the intelligent components that will drive the next generation of intelligent warehouses.

Conclusion: Your Next Step Towards a More Efficient Warehouse

The path to a competitive and future-proof logistics operation runs directly through automation. It is the definitive strategy for meeting the modern demands of speed, accuracy, and cost control. As we have seen, while the system’s intelligence lies in its software, its physical prowess is fundamentally enabled by the robust, reliable, and powerful technology of pneumatics. From the high-speed sorting line to the intricate grip of a robot, using compressed air provides the decisive force that makes automation possible. The integration of these components highlights the importance of industrial automation products in enhancing operational efficiency.

Building a successful automated system hinges on making intelligent choices at every level, especially with the foundational components that perform the physical work. The quality and engineering of your pneumatic systems will directly dictate the reliability and efficiency of your entire operation.

Take the next step in optimizing your facility. Contact our experts today for a complimentary assessment of your automated warehouse’s pneumatic needs, and let us help you build a system that is not just automated, but truly resilient.