In the ruthless world of contemporary business, the warehouse floor has emerged as the most important operational centre. For almost all operators, the truth is a constant battle against three overwhelming forces: an explosion in order volumes driven by e-commerce, a chronic lack of skilled workers, and the unstoppable increase in labor costs. The old system of manual picking, where warehouse workers have to walk miles of aisles for item retrieval, is not only inefficient anymore, but it is a direct survival threat. This is where warehouse automation becomes essential.

Automated warehouse pickingis the ultimate solution to this dilemma and a strategic necessity for any progressive supply chain. This is not a futuristic idea; it is the vital operational heart of the contemporary logistics network. It represents a radical change from dependence on human workers to the strategic use of advanced technologies to reach a new level of speed, accuracy, and operational efficiency.

However, this guide is not just another high-level description of the robots you can see on the floor. We are going behind the curtain to shed light on the key elements that enable these systems—the strong, dependable, and frequently ignored components that perform millions of accurate movements daily. We are discussing pneumatic parts. At the conclusion of this article, you will not only have a full picture of the automated warehouse ecosystem but also have the knowledge to choose the building blocks that will determine the success and sustainability of your own automation projects.

What Is Automated Warehouse Picking? A Foundation for Efficiency

In its simplest form, automated warehouse picking is the tactical use of robotics, warehouse management software, and mechanical systems to access stored items for order fulfillment. It is the systematic substitution of manual tasks, which are prone to human errors, with technology-based picking processes that are repeatable, measurable, and scalable, leading to improved warehouse productivity.

To understand its effect, one can look at the difference between it and its manual predecessor. A manual picking process is by its nature constrained by human endurance, precision, and the physical warehouse layout. These limitations are broken by automated systems in four major dimensions:

| Dimension | Description |

| Speed | Automated systems operate 24/7 without fatigue, achieving speed and consistency that far exceed human capability. G2P systems boost productivity and enable faster order fulfillment. |

| Accuracy | Manual methods may have an error rate of 1–3%, leading to costly returns, reduced customer satisfaction, and inventory issues. Automated systems, controlled by WMS and barcode scanning, reduce this error rate to nearly zero, ensuring correct item picking for customer orders. |

| Safety | Warehouses can be dangerous environments. Automation reduces the physical strain on employees from repetitive, demanding tasks like lifting heavy boxes, significantly lowering workplace injury risks and reducing the need for extensive safety training. |

| Scalability | Manual operations struggle to scale during peak seasons; adding more human pickers causes congestion and diminishing returns. Automated picking systems are designed for scalability, adapting to demand spikes with predictable effectiveness—often requiring only software adjustments or the addition of modular robotic units. |

The main business goal of implementing this technology is not merely to purchase new equipment. It is to radically re-engineer the financial and operational performance of a distribution center through continuous improvement. The objectives are straightforward: dramatically cut the cost-per-pick, multiply the order fulfillment process capacity, and maximize space utilization of all available space.

The Core Systems Powering Modern Warehouses

In order to value the role of components, one needs to comprehend the machinery that they enable. The automated warehouse picking landscape is characterized by different types of advanced warehouse picking systems aimed at addressing specificoperational needs. An understanding of this technology shows a mastery of the industry, forming the basis on which good investment decisions are made.

Goods-to-Person (G2P) Systems: Bringing the Inventory to the Worker

The G2P philosophy is the opposite of the conventional warehouse model. Rather than having workers move to goods, robotic systems bring the necessary inventory to a fixed picking station. This saves on wasted travel time, which may take up more than half of a picker’s shift, significantly reducing walking time. Key technologies include:

- Automated Storage and Retrieval Systems (AS/RS): These are tall, dense storage systems where cranes and shuttles travel vertically and horizontally on fixed tracks to store and retrieve totes, bins, or pallets at very high speed and accuracy. This category also includes vertical lift modules and conveyor systems.

- Shuttle Systems: Highly agile robotic shuttles move autonomously on every level of a storage rack, providing enormous throughput and flexibility as part of modern retrieval systems.

- Autonomous Mobile Robots (AMRs): These intelligent, floor-based robots move freely around the warehouse, detecting and moving complete shelving units to picking stations, representing a leap in technological advancements.

These machines are wonders of technology, but they can only be as efficient as the parts that make them physically move. Whether it is the fast removal of a bin by the shuttle or the accurate lift of an AMR, that power and dependability is the result of the actuators and drivers that are tirelessly at work in the machine.

Robotic Picking & Sorting: The Future of Order Fulfillment

Where G2P systems take inventory of an individual, robotic picking is intended to automate the last stage of the order picking process: the physical act of picking up an individual item.

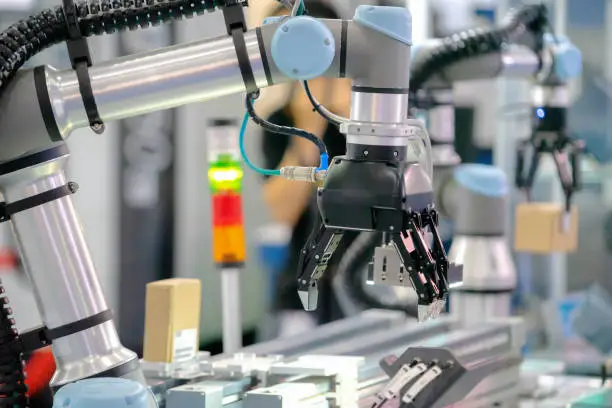

- Robotic Arms (Piece Picking): These robotic arms have high-end 3D vision systems and advanced grippers, allowing them to locate, approach, and pick single items from a bin of mixed SKUs. They hold the key to true end-to-end automation, often working alongside humans as collaborative robots.

- High-Speed Sortation Systems: After picking, items should be sorted for shipping. Automated sorters use a conveyor, diverter, and scanner system to direct thousands of items per hour to the appropriate outbound lane or packing station, streamlining fulfillment processes.

The actual effectiveness of a piece-picking robot is defined at the wrist by the end-of-arm-tooling (EOAT). A strong robotic arm cannot work without an end effector that can be adjusted to a huge range of product shapes, weights, and textures. This is where pneumatic grippers, with their unmatched speed, flexibility, and controlled force, have become the most popular choice among innovators. Other picking solutions like light systems (pick-to-light) or systems using voice commands based on verbal instructions also enhance picking operations, but the physical handling is often perfected by pneumatics.

Pneumatics at Work: The Power and Precision of Automated Picking

The large systems of automation receive the focus, yet their functionality depends on the performance of smaller, more important parts. The basic technology that drives millions of these important actions is pneumatics—the technology of using compressed air to provide force and motion. This technology offers the raw power for high-force applications and the fine control for delicate manipulation, making it a cornerstone of automated picking solutions.

Why Pneumatics? The Perfect Fit for Warehouse Automation

Pneumatic systems are not just an option; in most warehouse operations, they are the better choice because they have a strong list of inherent benefits:

- Cost-Effectiveness: Pneumatic components have an impressive power-to-cost ratio and can be a more cost-effective solution for producing linear motion and gripping force than electric ones.

- Speed: Pneumatic actuators and grippers can be operated at very high cycle speeds because compressed air can be discharged quickly, which is necessary in high-throughput sorting and picking processes.

- Reliability and Durability: Pneumatic systems are mechanically simple and strong. They are known to be tough in places that are usually full of dust, debris, and changing temperatures—conditions that other delicate electronic parts would not withstand.

- Overload Protection: A pneumatic system may be stalled without damaging its parts. A similar electric motor would burn out. This safety feature is priceless in dynamic warehouse settings.

- Simplicity and Ease of Maintenance: The simple design of pneumatic cylinders and valves makes them easy to install, comprehend, and maintain, and does not require highly specialized technicians.

- Clean and Safe Operation: Using clean and dry air as a power source, pneumatics can be used in a broad variety of industries and are spark-free by nature, which makes them safe in certain environments.

Key Pneumatic Products in Action

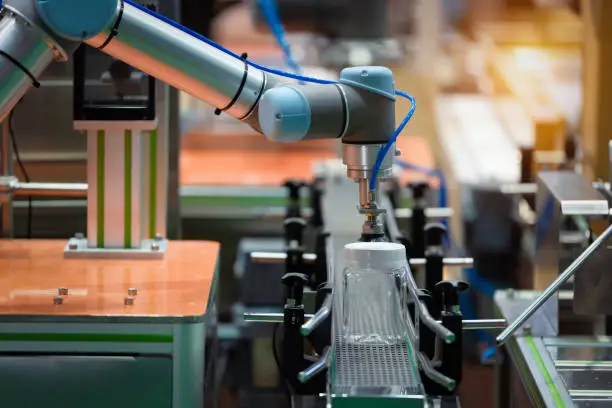

In an automated picking system, particular pneumatic elements play particular, important functions:

| Component | Description |

| Pneumatic Grippers | Widely used in robotic picking tasks due to their versatility. The same pneumatic system can gently handle fragile items like eggs and then, milliseconds later, apply a strong grip to heavy, irregularly shaped tools. With parallel or angular jaws, they can adapt to countless product geometries, making them ideal for dynamic inventories. |

| Air Cylinders and Actuators | The workhorses of linear motion, providing direct force for many tasks in distribution centers. They are used for pushing packages off conveyors, lifting totes in AS/RS, positioning items for labeling, or halting pallets. They deliver high-performance, high-speed, and repeatable motion in a cost-effective and simple design. |

| Vacuum Technology | A pneumatic subdivision that includes suction cups and generators, designed for flat, smooth, or sealed surfaces. Perfect for depalletizing uniform cartons, handling products in plastic bags, or accurately picking sheets of material. |

| Valve Terminals and Air Preparation | Valve terminals act as the control interface for actuators, receiving signals from the PLC to regulate compressed air flow precisely. Air preparation units (Filter-Regulator-Lubricator) ensure compressed air is clean, dry, and at the correct pressure—critical for maintaining long-term reliability of all pneumatic components. |

The Business Case for Pneumatics in Your Automated Warehouse Picking System

For the warehouse management team, including the operations manager or CFO, the choice to invest in a particular technology should be based on a clear return on investment. The decision to use pneumatic elements in an automation system is a good business move supported by concrete financial and operational advantages that provide a competitive edge.

Lowering Total Cost of Ownership (TCO)

The original cost of the components is not the only financial equation. TCO gives a more holistic view, and this is where pneumatics shine. The low initial cost of pneumatic cylinders and valves, their long life, and low maintenance needs lead to a much lower TCO than more complicated electromechanical options throughout the system life.

Boosting Reliability and Uptime

Any minute of downtime in a high-volume distribution center is a direct blow to the bottom line. The conditions in the warehouse are harsh—dust, vibrations, and changes in temperature are the order of the day. Pneumatic systems are mechanically strong and designed to withstand such conditions. Their established reliability is directly converted into increased uptime, increased system availability, and more predictable operational throughput, which protects revenue and ensures accurate order fulfillment.

Unlocking High Speed and Efficiency

Pneumatic componentscan be actuated and cycle at very high rates due to the physics of compressed air. Cycle time is an important KPI in applications such as sorting, diverting, and robotic piece-picking. The quick reaction of pneumatic valves and the speed of cylinders and grippers allow the whole system to work faster, which directly increases the number of orders that can be processed and shipped in an hour, improving warehouse efficiency.

How to Choose the Right Pneumatic Partner for Your Automation Project

When choosing the right pneumatic partner for your automation project, quality and certifications should be the first consideration. At Hebai-Omch, we take pride in delivering components that meet the highest international standards, including ISO 9001, CE, CCC, and ROHS. Our cylinders, valves, fittings, and accessories are manufactured with strict quality control, ensuring durability, reliability, and safety. By maintaining rigorous standards, we give our customers the confidence that their production lines will operate smoothly without costly interruptions.

Equally important is the breadth and depth of the product line, along with the technical expertise to support unique applications. Hebai-Omch offers over 30 categories, 200 series, and 3,000 models of automation components, giving customers access to one of the most comprehensive portfolios in the industry. Beyond variety, we provide flexible customization such as stroke length, bore diameter, and material selection to tailor solutions to specific project requirements. Our experienced engineering team is always ready to validate technical details, solve application challenges, and propose efficient alternatives that meet or exceed expectations.

Finally, supply chain stability plays a decisive role in ensuring projects run without disruption. With seven automated production lines, a nationwide network of 86 branches, and strategically located warehouses, Hebai-Omch secures a fast and reliable delivery system supported by same-day shipping and real-time logistics tracking. This infrastructure minimizes downtime, keeps inventory optimized, and guarantees a seamless supply of high-quality parts. As a trusted partner, Hebai-Omch not only delivers products but also provides expertise, reliability, and long-term support to help your business grow stronger and stay competitive.

Conclusion

The shift toward automated warehouse picking is no longer a matter of if, but when. It is the necessary evolution for any business seeking to thrive in a world of increasing consumer demand. While the towering robotic systems and intelligent software are the visible face of this revolution, their success is built upon a foundation of powerful, reliable, and efficient components.

Pneumatic technology,with its unmatched blend of speed, durability, and cost-effectiveness, remains a cornerstone of high-performance automation. The decision to invest in high-quality pneumatic grippers, cylinders, and control systems is not merely a component-level choice. It is a direct investment to streamline operations, enhance profitability, and ensure the long-term resilience of your entire logistics operation.

Ready to build a more efficient future for your warehouse?

- Consult with an Expert: Ready to power your automated warehouse picking system with reliable pneumatic solutions? Contact our engineering team today for a free application consultation.

- Deepen Your Knowledge: Want to see more real-world examples? Please click this to discover more automation knowledge:https://www.omchele.com/applications/

- Explore Our Solutions: Browse our online catalog to discover a full range of pneumatic products designed specifically for the rigors of logistics automation.