Introduction: The Unstoppable Wave of Warehouse Automation

The requirements of contemporary business and industrial processes are enormous. The fast development of e-commerce, and the customer satisfaction demands of instant delivery, have put the global supply chain under pressure like never before. This fast-paced, high-volume environment demands that warehouses and any distribution center operate as hubs of hyper-efficiency, improving the order fulfillment process with a speed and accuracy that was once unheard of.

Over the years, the only way to expand the capacity of current operations was to employ more people. Nevertheless, this model has hit its practical ceiling because of the constant labor shortages and the limitations of manual material handling. This has left businesses, particularly in regions like the United States, with a crucial choice. Automationis no longer a strategic option to achieve a competitive advantage; it is a basic necessity to remain viable and achieve future growth. Automated Material Handling (AMHS) is the logical next step that any business needs to take in order to overcome its material handling challenges.

This paper will give an in-depth discussion of this technological change. We will define automated material handling, discuss the major operational advantages it offers, and outline the different types of technologies that make up these material handling systems. Critically, we will also shed light on the fundamental relationship between these large-scale systems and fundamental technology: pneumatics. It is a major technology in physical actuation, converting digital material information into precise action and creating a synergy that is perfect to enable the automated future.

What is Automated Material Handling (AMH)? A Clear Definition

An automated material handling systemis not a single machine but an integrated ecosystem. It is the use of engineering and logistics to transport, store materials, protect, and manage everything from raw materials to finished goods in all operational processes, with the aim of reducing human intervention. It can be best described as a very well-coordinated system whereby machinery, control systems, and software work in unison to accomplish a particular set of logistical objectives and streamline the material handling process.

This ecosystem is constructed on three pillars.

- The first is the actual material handling equipment, robotics, conveyors, and retrieval systems that do the physical work.

- Second is the control system, the layer of programmable logic controllers (PLCs) and sensors that coordinate the movements of the machinery with precision.

- The third and most important is software, which is often a Warehouse Management System (WMS) that controls the whole process.

This software gives the intelligence, processing orders, managing inventory, and dispatching commands for the routing and delivery of material to the control system in the most efficient sequence possible.

The end result of AMH is to have a smooth, continuous material flow. This is done by converting the unpredictable and variable nature of a manual warehouse into a predictable, data-driven, highly optimized operation by replacing variability with reliability and human effort with machine endurance.

The Core Benefits: Why AMH is a Game-Changer for Your Operations

*This video showcases Toyota Material Handling Automated Solutions, highlighting the benefits brought by automation.

The choice to invest in an AMH system is a major one, but the payoff is reflected in all the key measures of an operation. It is not just a small step forward but a paradigm shift in the capabilities of a facility, providing compounding benefits that redefine what can be done in terms of speed, safety, and scale.

Skyrocketing Efficiency and Unlocking 24/7 Productivity

The first and the most significant effect of AMH is on operational efficiency. In a manual warehouse, the productivity is directly connected to human labor—to shift changes, breaks, and the physical capabilities of its workforce. These limitations are eliminated by an automated system. It works at an optimal, steady rate, 24 hours a day, 7 days a week, 365 days a year, except during scheduled maintenance. This enables a company to separate its expansion from the supply of the local workforce. The efficiency gains are staggering. The travel time it takes to fulfill orders that used to take hours can be reduced to minutes. Automated systems are able to move, sort, and retrieve items much faster than humans, and are able to do so consistently and without fatigue. A robotic arm can palletize heavy boxes and cartons all through a shift without taking a break, and an AMR can traverse a large facility with optimized routes that do not waste any motion. This high-speed, continuous operation significantly boosts the throughput of a facility, enabling it to process a greater number of orders in the same physical footprint.

Enhancing Workplace Safety and Achieving Near-Perfect Accuracy

Warehouses and manufacturing floors are dangerous places. The lifting of heavy materials, the use of forklifts in crowded aisles, and the monotony of picking and packing are some of the factors that cause a large number of workplace injuries. A well-designed material handling system systematically designs these risks out of the process, improving ergonomics and reducing the risk of injury. Robots are given physically strenuous and repetitive tasks—lifting heavy objects like pallets and totes, reaching high shelves, and doing monotonous tasks—which are the main causes of injury. This transition safeguards workers, minimizes insurance costs, and creates a safer working environment where human beings are transitioning to system monitoring, maintenance, and strategic planning with less directhuman interaction.

At the same time, automation introduces a new degree of accuracy. Human error in picking, sorting, or inventory counts is a known, but expensive, component of manual processes. A misinterpreted label or a misplaced product can lead to shipping delays, expensive returns, and unhappy customers. Barcode-driven, RFID-based, and software-driven systems have an accuracy rate that is frequently above 99.9%. Each item is monitored, each movement is confirmed, and the whole inventory is visible in real-time, which sets a high level of operational reliability and avoids bottlenecks.

Slashing Operational Costs and Optimizing Your Facility’s Footprint

Although the initial capital cost of AMH may be high, the operational savings are very attractive in the long run. The most obvious saving is the decrease in the use of manual labor, which eliminates the problem of recruitment, training, turnover, and increasing wages. However, the savings are much more than payrolls. The significant decrease in errors translates to fewer returns and less wastage of product. Optimized material flow and less product damage during handling a wide variety of items also has a direct impact on the bottom line. One of the most important advantages of AMH is that it can maximize physical space. This is especially so with Automated Storage and Retrieval Systems (ASRS). These systems are built to use a racking system and vertical space, going as high as manual equipment is impractical and working in very narrow aisles. This method can raise storage density by as much as 85 percent, enabling a company to store much more product in an existing facility or to build a smaller, more cost-effective new one. This spatial optimization is a huge financial benefit in an age of high real estate prices.

A Look Inside: Key Technologies that Power AMH Systems

The strength of AMH is in the advanced interaction of a number of technologies that provide effective material handling solutions. Although an integrated system has many components, these are the main functional units of the automated environment that play a specialized and critical role.

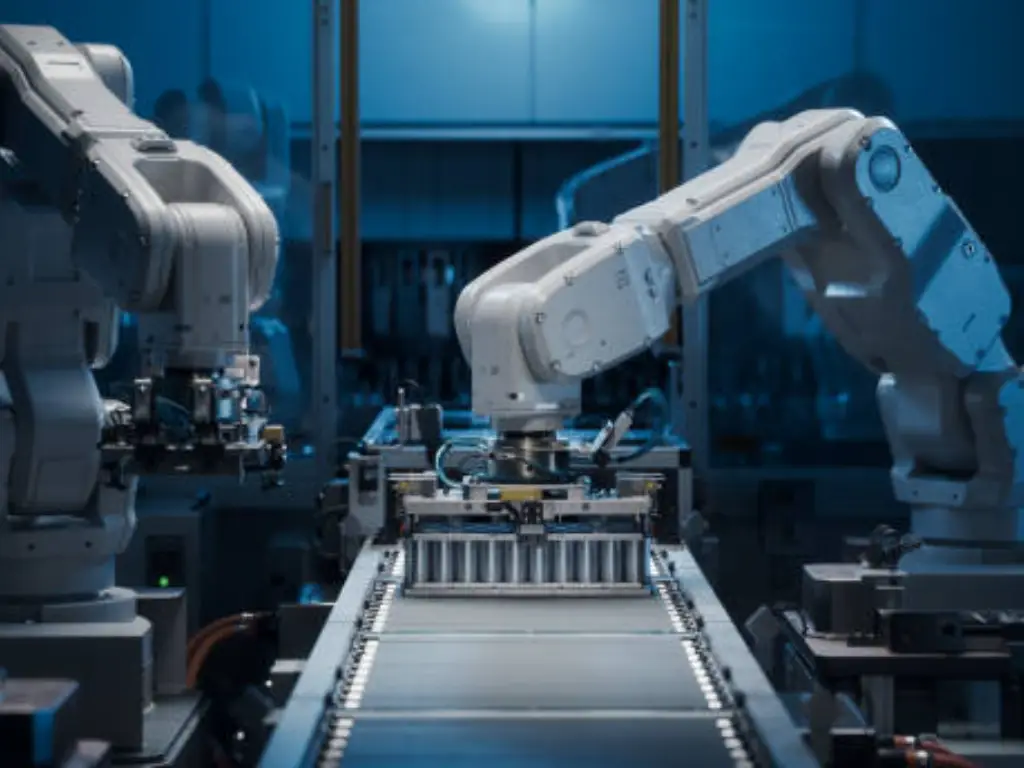

- Robotic Systems: The Hands of Modern Automation: Robotic systems are the versatile, moving parts of AMH. This type encompasses articulated robotic arms, which are fixed, but very flexible, and are used in repetitive, but complex tasks such as palletizing and depalletizing, case packing, and machine tending. They are fast, strong, and precise, which is impossible to achieve with manual labor. A more recent and more important type is mobile robotics, such as autonomous vehicles like AGVs that follow fixed routes and AMRs that use advanced sensors and AI to navigate dynamically to their next destination. These robots offer a smooth and adaptable way of moving a variety of products from storage to packaging areas or between manufacturing cells, including in the demanding semiconductor industry.

- Conveyor & Sortation Systems: The Arteries of the Facility: Conveyor systems and sortation systems form a high-velocity network for transporting a huge amount of goods along fixed routes with great efficiency. Contemporary conveyor systems are smart networks that have sensors, scanners, and pneumatic controls that monitor and guide items. They can easily be incorporated with other technologies, feeding items to robotic packers or receiving goods out of storage systems. A key sub-category is high-speed sorters, which can divert thousands of packages per hour to particular shipping lanes or packing stations based on barcode information, and are therefore vital to high-volume e-commerce and fulfillment operations requiring high throughput.

- Automated Storage & Retrieval Systems (AS/RS): The Brains of High-Density Storage: ASRS technology is the ultimate solution to high-density and high-speed inventory management. An AS/RS is a tall rack system, an inventory management software system, and automated machines, which retrieve and store items, such as cranes or robotic shuttles. When a particular item is required, the software identifies it and sends a machine to retrieve the tote, bin, or pallet and bring it to an operator at a goods-to-person workstation. This removes most of the non-productive time in a warehouse: the time that an employee spends walking and searching for items. The system retrieves the items and the human operator can concentrate on value-added activities such as packing and quality control.

The Crucial Connection: Where Pneumatics Fit into the AMH Puzzle

In the area of Automated Material Handling (AMH), the focus is usually on high-tech software and robotics. However, the practical interface that makes these technologies workable is frequently based on a well-developed and surprisingly robust technology-pneumatics.

Control and Physical Action

In AMH, pneumatics are the necessary connection between digital instructions and mechanical movement. Pneumatic systems use compressed air, a clean, cost-effective, and abundant resource, to convert signals into reliable, fast actions. This ability gives the strength and motion to perform actual work in a dependable and efficient manner.

Robotic Systems Applications

Pneumatics are essential in robotic automation, especially in End-of-Arm Tooling (EOAT). Pneumatic grippers provide the power and accuracy to safely grip boxes, parts, and finished goods. Vacuum cups offer a soft but firm hold on delicate or oddly shaped objects. The fast speed of these devices contributes to the high cycle times that characterize the worth of robotic systems.

Conveyors, Sortation, and AS/RS

In addition to robotics, pneumatic actuators are used in conveyors and sortation systems to drive diverters, stoppers, and pushers through millions of cycles with rugged reliability. In Automated Storage and Retrieval Systems (AS/RS), pneumatics are applied in shuttle locks, positioning devices, and light-load lifts at goods-to-person stations. In both instances, they offer a cost-efficient, long-lasting, and high-performance source of motion.

Conclusion

Whether it is high-speed robotics, complex sortation lines, or advanced storage systems, pneumatics are the silent workhorse of AMH efficiency. They are not only a link between command and action, but the invisible power that guarantees reliability, speed, and cost-effectiveness of the whole system — from inbound handling to end of line packaging.

Choosing the Right Partner: How High-Performance Pneumatics Elevate Your AMH System

- Maximize Uptime: Reliable Quality, Delivered Fast

- Simplify Sourcing: 3,000+ Models from One Partner

- Built to Last: Lower Your Maintenance & Replacement Costs

- Tailored Solutions to Win Your Market

Choosing the wrong pneumatic components can result in frequent downtimes, reduced precision, and overall system inefficiency, leading to costly operational disruptions. For an AMH system that relies on consistent performance, selecting high-quality and reliable pneumatic components is crucial to ensure smooth and uninterrupted operations.

At Hebai-Omch, we specialize in providing high-performance pneumatics, renowned for their exceptional reliability and long lifespan. Our products are designed to keep your AMH system running seamlessly 24/7, minimizing downtime and maximizing productivity. With our precision pneumatic control valves and pneumatic cylinders, you can achieve microsecond-level response times, significantly improving the accuracy of robotic gripping and enhancing your system’s overall efficiency.

In addition to our high-quality standard offerings, we provide flexible customization options to meet the specific needs of your AMH system. Our expert team is ready to deliver tailored solutions that ensure optimal performance in your unique application scenarios. Contact our engineers today for a free professional evaluation and let us help you elevate your AMH system with Hebai-Omch’s advanced pneumatic solutions.

The Future Outlook: What’s Next for AMH and Pneumatic Technology?

The evolution of automated material handling is continuing. The next stage involves creating systems that are not just automated, but truly intelligent and adaptive, with high scalability. The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is creating highly data-driven facilities. AI will enable predictive logistics, allowing systems to anticipate demand and reconfigure material flows on the fly. IoT sensors embedded throughout the system will provide an unprecedented level of real-time data on machine health and performance.

Pneumatic technology is evolving in parallel with this trend. The future is “smart pneumatics.” This involves embedding sensors directly into pneumatic components like cylinders, valves, and grippers. These sensors can monitor pressure, position, temperature, and cycle counts, feeding this data back to the central control system. This enables predictive maintenance, allowing a system to flag a component for replacement before it fails, virtually eliminating unplanned downtime. It also allows for real-time performance optimization, as the system can adjust air pressure and flow to maximize efficiency and minimize energy consumption. A modern automated warehouse system increasingly relies on pneumatic solutions to maximize uptime and operational efficiency.This fusion of reliable power and digital data ensures that pneumatics will remain a core enabling technology for the next generation of AMH.

Conclusion: Your Next Step Towards a Seamlessly Automated Future

The shift toward automation isa fundamental restructuring of the industrial and commercial landscape. Automated Material Handling systems are essential infrastructure for any business that aims to compete on speed, accuracy, and scale. As we have seen, these sophisticated systems are a functional synergy of intelligent software and robust hardware. At the heart of that hardware, performing crucial physical work with unwavering reliability, is pneumatic technology. In fact, an efficient automated warehouse system relies heavily on integrated pneumatic solutions for smooth operation. It is the proven, powerful, and increasingly intelligent method for bringing digital instructions to life. Building a world-class AMH system requires sourcing high-quality, durable components.

By choosing a partner dedicated to precision, durability, and innovation, you ensure that your investment in automation is sound. To explore how our advanced pneumatic solutions can be an integral part of your automation strategy, browse our product catalog or connect with a specialist today.