Introduction: The Engine of Modern Manufacturing

In modern industry, the automated assembly line is a pivotal force. It drives the manufacturing process in factories worldwide, enabling the mass production of everything from microchips to motor vehicles. In a world where the pressure to meet escalating market demands with speed, accuracy, and economy is unremitting, the rise of automation is no longer just a strategic benefit but a requirement for survival and growth. The sophistication and reliability of production systems often measure the gap between market leaders and their competitors.

This article is an in-depth discussion of assembly line automation. We will proceed systematically, starting with the concept of the assembly line and explaining what this technology is and why it has become so central. Then we will explore its fundamental advantages, dissect its complicated anatomy, and look at the key elements that guarantee its performance. Lastly, we will scan the various kinds of automation solutions out there and look toward the future of technological trends that will define the smart factories of tomorrow. We aim to provide a comprehensive map for comprehending this revolutionary power in manufacturing.

What Is an Automated Assembly Line? A Foundational Definition

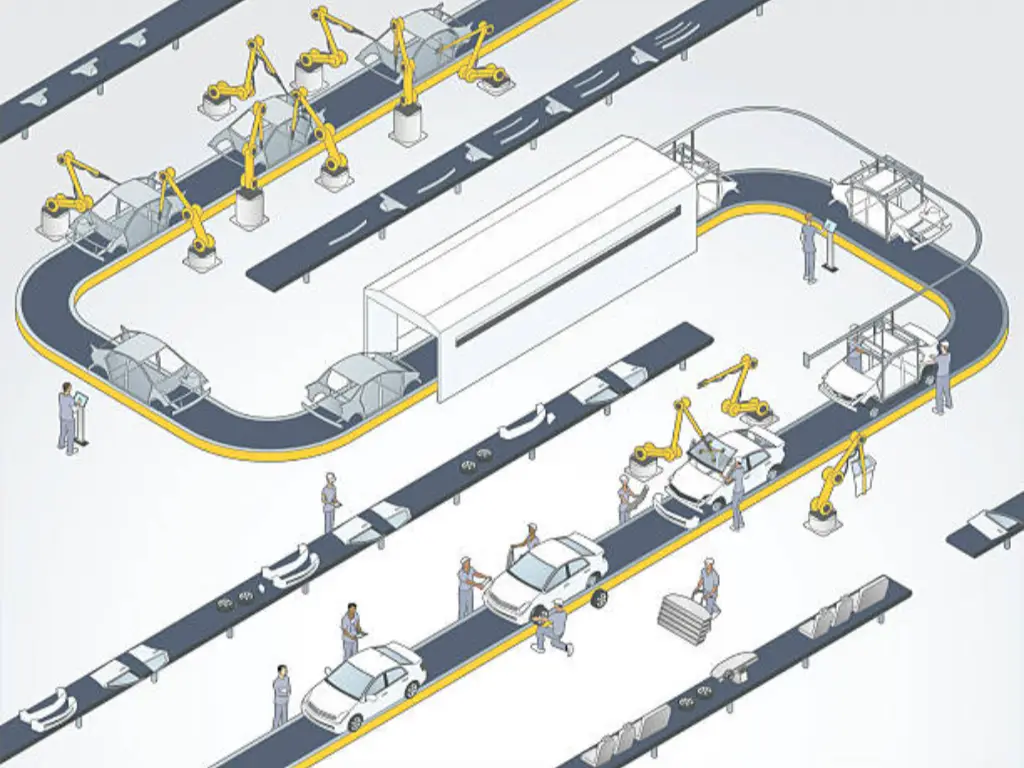

Fundamentally, a fully automated assembly line is a combined manufacturing system where raw materials or sub-assemblies are transported through a series of workstations to create a complete product with little to no direct human intervention. This assembly process is a complex interaction of automation equipment, robotics, and a control system, all working in a strictly choreographed sequence of operations.

The distinguishing features of a real assembly line are:

- Sequential Processing: The product follows a pre-defined route, and a specific task is carried out at each station in a certain sequence. This logical flow ensures that every step is done properly before the next one starts, standardizing the entire production process.

- Intense Automation:Assembly tasks that were previously done by human workers, including fastening, welding, and packaging, are carried out by special assembly machines and industrial robots. The role of human participation changes to supervision, maintenance, and quality control.

- Continuous Flow: The system is intended to be operated continuously or nearly continuously, usually 24 hours a day, seven days a week. This maximizes asset utilization and provides a predictable, consistent output not limited by a conventional workforce.

- Integrated Control: A central control system coordinates the whole production line. This system ensures that every machine, robot, and transport mechanism is in perfect harmony. It determines when, how fast, and how each action on the line is performed.

The combination of these factors transforms the manufacturing process from a series of fragmented, labor-intensive processes into one, unified, and highly efficient production system.

Why It Matters: The Core Benefits of Driving Adoption

The rationale of the widespread use of automation is obvious and strong. Companies that invest in this technology realize high, measurable returns that have direct impact on their competitiveness and bottom line. The four main benefits are:

- Improved Productivity and Throughput: An automated system operates with a speed and consistency that is impossible to achieve with manual labor alone. Robots don’t get tired, need breaks, or lack concentration. This enables a much shorter cycle time and higher throughput, leading to a drastic rise in the number of units produced per hour. Factories can operate 24 hours a day to satisfy growing market demands and reduce the lead time between order and delivery.

- Better Product Quality and Consistency: Human error is an inevitable variable in manual assembly operations. Robotic automation virtually removes this variable. Every task is done to the same specification and precision, every time. A robot will screw a bolt to the correct torque, apply the correct amount of adhesive, and weld with the same precision. Such a high level of repeatability results in better product quality, a radical decrease in defect rates, and a decrease in material waste due to rework and rejections.

- Lower Long-Term Operational Costs: Although the initial costs of an automated line may be high, the long-term payback is high. The most immediate saving comes from reduced labor costs. Moreover, automation reduces the waste of materials due to its accuracy. More efficient energy consumption is also achieved through optimized, computer-controlled processes. These cumulative savings greatly exceed the initial outlay over time, resulting in lower production costs per unit.

- Greater Workplace Safety: The factory floor can pose a lot of hazards to human beings. Automated assembly lines remove human workers from hazardous and ergonomically difficult jobs, including handling heavy parts, hazardous materials, or performing highly repetitive tasks that may cause strain injuries. When companies delegate these tasks to machines, they can provide a safer working environment and greatly decrease workplace accidents.

To sum up, the fundamental advantages of automation, such as increased productivity, product uniformity, cost savings, and safety in the workplace, are a strong case in favor of its extensive use. These benefits will only increase as technology keeps on improving and assist businesses remain competitive and address the needs of a constantly changing market.

The Anatomy of Automation: How a System Comes to Life

To fully comprehend an automated assembly line, one should not only look at the final product but also its complex internal design. A system is not an isolated object but a complicated ecosystem of interrelated sub-systems, each of which plays a crucial role.

The Control System: The “Brain” of the Operation

The control system is the command center of the whole assembly line, where digital instructions are converted into physical action. This is normally controlled by a Programmable Logic Controller (PLC) or Industrial PCs (IPCs). These hardened computers are coded with the particular sequence of operations for the assembly process. Sensors on the production floor feed them with continuous input data—whether it is the presence of a part, its correct position, or if a task is complete. According to this data collection, the control system transmits accurate output commands to all motors, valves, and robots, coordinating the whole production process with high precision.

The Material Handling System: The “Circulatory System”

The material handling system is responsible for ensuring that materials and products move continuously and on time along the production line. Its role is to move parts and assemblies between stations so that no part of the line is short of materials or blocked by a completed part. This system may be in various forms, such as a simple conveyor belt for linear product movement, or Automated Guided Vehicles (AGVs) which move around the factory floor to deliver parts with more flexibility. The effectiveness of this system is the most important way to avoid bottlenecks and maximize throughput.

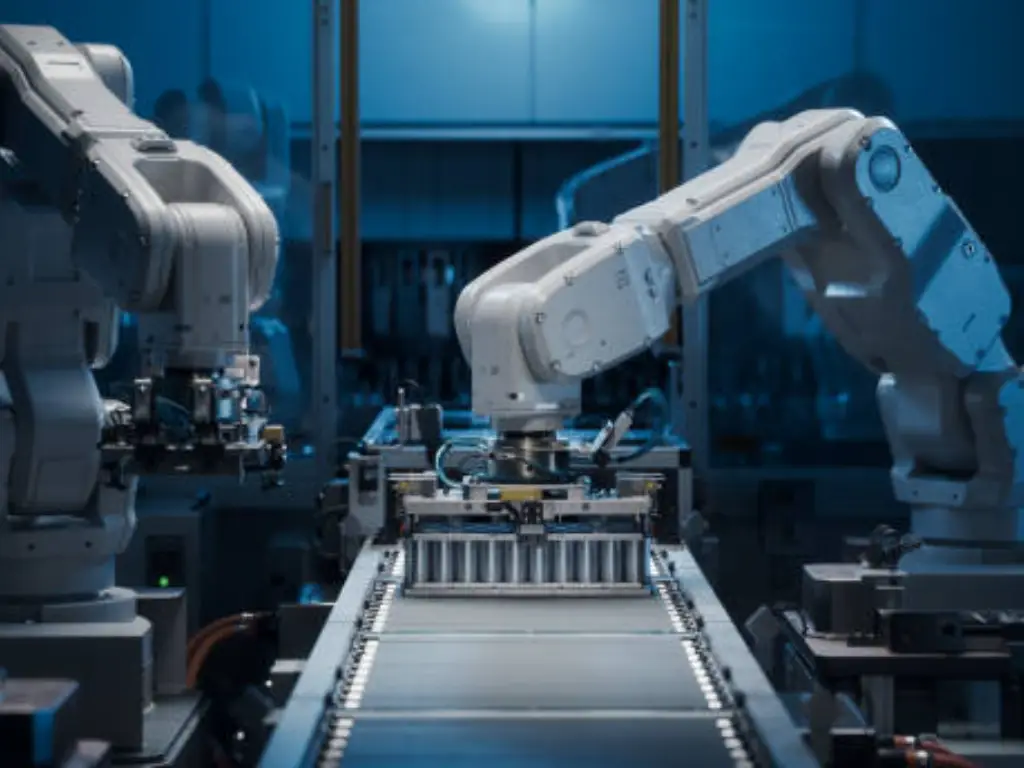

Robotic & Mechanical Actors: The “Hands” of the Line

These are the parts that perform the physical assembly tasks. This group encompasses a broad range of technologies, from multi-axis robotic arms with the ability to perform complex tasks like welding, to high-speed SCARA robots used for pick-and-place operations. Every robot has a special end-effector a gripper or a welding torch—which is designed to perform a specific task. In addition to robots, there are special mechanical stations that carry out simpler and more repetitive tasks such as pressing or stamping. The ability and effectiveness of the line is determined by the synergy of these different tasks performed by various actors.

The Unsung Heroes: Why Quality Components Are Your True Foundation

In the world of automation, people are often captivated by grand production lines, complex system architectures, and intelligent controls, while overlooking the “unsung heroes” hidden behind them. In reality, it is the countless small yet critical components that form the true foundation of the system. Their performance, reliability, and precision directly determine the efficiency and stability of the production line. With 37 years of industry experience, we at Hebai-Omch understand that every cylinder, valve, fitting, and tube plays a vital role in supporting our customers’ production rhythm. Through rigorous quality management and international certifications (ISO 9001, CE, CCC, ROHS), we ensure that these fundamental components perform consistently, keeping equipment running reliably over the long term.

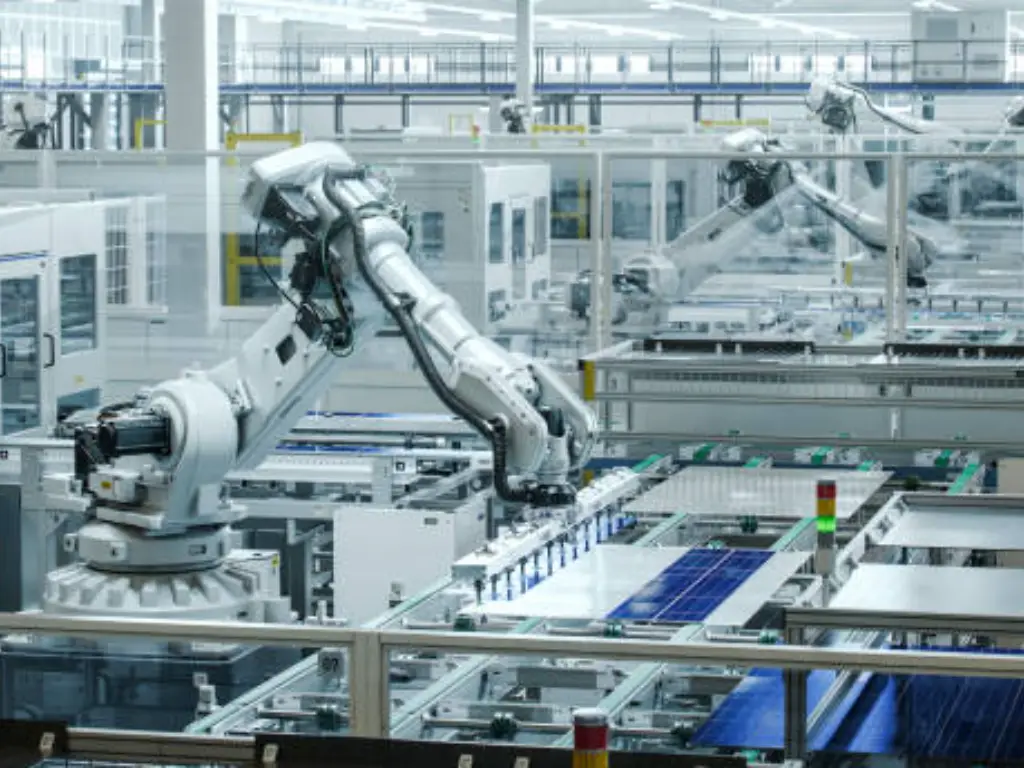

In modern industrial automation, pneumatics is the driving force behind speed and precision. Cylinders, valves, and pneumatic grippers are not only valued for their rapid response and flexibility but also for their cost-effectiveness, making them essential across industries. At Hebai-Omch, we embrace this value by using premium materials and advanced technologies, ensuring that our pneumatic components deliver micron-level precision and zero failure even under thousands of high-frequency cycles per minute. Whether it is precise assembly in electronics manufacturing or high-speed production in the automotive industry, our pneumatic products provide lasting efficiency and stability, enabling our customers to stay ahead in a competitive market.

Every production line has its own uniqueness, and the balance between standardization and flexibility is the key to competitiveness. That is why we not only offer a wide portfolio covering 30 categories, 200 series, and 3,000 models but also provide customization options such as stroke length, bore diameter, and material selection. With seven advanced production lines and an annual capacity of 20 million units, we respond quickly to market needs, and through 86 branches across China, we ensure same-day shipping and efficient service. Partnering with Hebai-Omch means gaining not just high-quality components, but also a trusted partner who understands your needs and empowers your growth.

Types of Automated Assembly Lines: Finding the Right Fit

Automated assembly lines are not universal. They are programmed to address certain production requirements in terms of volume, product complexity, and variety. The main types include:

| Automation Type | Description |

| Fixed (or Hard) Automation | This system is set up to manufacture one standardized product in very large quantities. The sequence of operations is predetermined and embedded into the equipment. These lines are very efficient and fast but not flexible. Reconfiguring them for a different product is a big task. They are prevalent in various industries, especially automotive manufacturing. |

| Programmable Automation | This system is used in batch production where a medium to high quantity of similar products is produced. The equipment can be reprogrammed to suit various product sizes and assembly patterns. Changeovers can be made but can be time-consuming to reprogram and retool. |

| Flexible (or Soft) Automation | This is the most flexible system, used in environments with high product diversity and reduced production volumes. It frequently involves a system of computer-controlled machines and advanced robotics that can be reprogrammed quickly to work with other products. This flexibility reduces changeover time and is therefore suitable in industries like consumer electronics and medical devices. |

The selection of the appropriate kind of automated assembly line is based on a number of factors such as the volume of production, the complexity of the product, and the flexibility requirements. Fixed automation is best suited to high volume, standardized production, and programmable automation provides a compromise between batch production and moderate flexibility. Flexible automation, conversely, is best suited to the environment with a variety of products and low-to-medium volumes of production, where flexibility and rapid changeovers are needed.

Knowing the advantages and disadvantages of each type, manufacturers can make the right choice and meet their own production objectives and market needs.

The Future Is Automated: Trends Shaping Tomorrow’s Factories

Automated assembly linesare not finished yet. The emergence of a new generation of sophisticated technologies is changing the factory floors into smarter, more connected, and more efficient. These inventions will transform the manufacturing process by improving the productivity and quality of the products, and the major trends will lead to these transformations.

The emergence of Industry 4.0 and the Internet of Things (IoT) is one of the major trends. IoT is the process of incorporating sensors into the assembly line to gather enormous volumes of data regarding performance, temperature, and stress. This information can be applied to predictive maintenance, where manufacturers can predict when a component may fail and carry out maintenance before it fails unexpectedly and causes downtime. The other disruptive trend is the combination of Artificial Intelligence (AI) and machine vision. The vision systems based on AI are transforming the quality control through deep learning algorithms and high-resolution cameras. These systems are able to scan products at unbelievable speeds and precision and detect even microscopic defects that human inspectors may overlook, which means that the quality of products will always be high.

Finally, collaborative robots or cobots are transforming the factory floor. Cobots are not only safe to work with human workers, unlike traditional industrial robots that work in isolation. These robots are used to perform repetitive work as human beings concentrate on more complex or delicate work, which forms a hybrid assembly model that makes the most of the capabilities of both human and machine labor.

Conclusion: Build Your Future on a Solid Foundation

The first step to realizing the enormous potential of the automated assembly line is to understand it, both in its original definition and its main advantages, as well as its complex anatomy and future outlook. It is a technology that has radically changed our world and will keep on shaping the future of manufacturing. Nevertheless, the final success of such advanced technology is always reduced to one simple rule: a system is as strong as its base. Quality of the core components of any automated line forms the basis of its long-term reliability and profitability. Selecting a business partner in these key aspects is not a mere purchase but an investment in your productivity and your future.

At Hebai-Omch, we provide certified and high-performance automation parts supported by decades of experience and a strong supply chain. Join us and we will guarantee you quality, delivery on time and a base that will support your future.